BatMan’s Breakthrough in EV Battery Manufacturing

BatMan’s Breakthrough in EV Battery Manufacturing

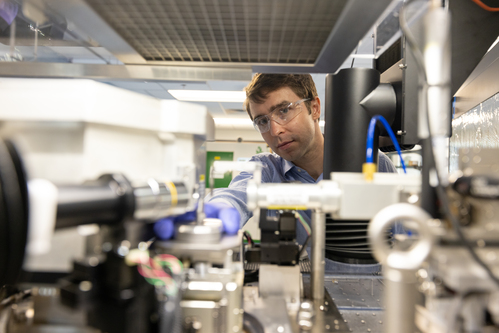

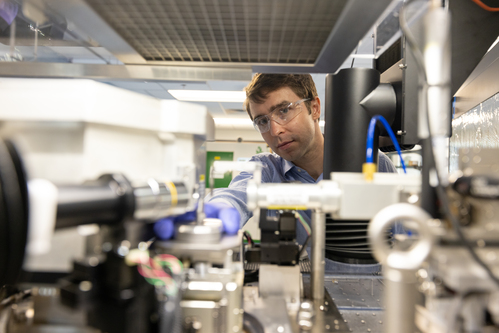

NREL researcher Donal Finegan used X-ray nano-computed tomography as one of the many tools to evaluate the performance of the laser-ablated battery electrodes.

A project led by researchers at the National Renewable Energy Laboratory in Golden, Colo., is looking to change the future of electrified transportation by optimizing battery charging speeds in EVs using laser ablation, advanced computational models, and materials characterization.

Project “BatMan” (taken from an abbreviation of battery manufacturing) is funded by the Department of Energy (DOE) and has received vital contributions from several scientists and researchers from NREL, partners in commercial battery manufacturing from Clarios, acoustic specialists from Liminal Insights, and the France-based Amplitude Laser Group.

The BatMan origin story

The project stems from research into the pain points facing EV customers and identifying the market segments that have the potential to be unlocked if those causes for hesitation are addressed.

Become a Member: How to Join ASME

“Customers don't want to be stopping on road trips for an hour or two to recharge their cars. And people without garages for overnight charging need the ability to charge quickly on the street,” said Donal Finegan, a staff scientist at NREL who specializes in understanding degradation and failure mechanisms of lithium-ion batteries. “If we can get fast charging down to 5 or 10 minutes, that's competitive with an internal combustion engine refuel, and we can alleviate that concern.”

Finegan explained that the limiting factor in fast charging lies in the graphite anode materials.

“If you try to charge too quickly, the lithium can't saturate the electrode fast enough,” Finegan explained. “An electrode in a lithium-ion battery looks like a miniature rice crispy treat. There are particles bound together under the porous matrix, and in between the particles is just empty space. Getting the lithium through that forest network and into all the particles of graphite is quite tortuous—it’s not just a straight path.”

This is where laser ablation comes in. To reduce the long and arduous path that lithium must travel, the BatMan project is using a new high-throughput laser patterning process to strategically structure the electrodes, creating “straight highways” for the lithium to quickly saturate deep into the electrode and enable faster charging.

One of the challenges the team faces in improving fast charging is to do so without sacrificing other priorities, such as affordability, range, and lifetime of the vehicle—metrics which have already largely been achieved by car makers.

“Laser ablation specifically as a technique is something we chose because we can create these 3D microstructures in the battery electrode in a fast way and process the electrodes with existing manufacturing capabilities,” said Tremolet de Villers.

While he emphasized that maintaining energy density is crucial, equally important for the team is making sure that the laser ablation technique can be integrated onto existing fabrication lines, compatible with current infrastructure and not requiring major factory changes. “We feel like that's a real benefit to a battery maker—to integrate this new process with minimal added cost to their manufacturing,” Tremolet de Villers added.

Entering the market

The BatMan project has successfully demonstrated the implementation of laser ablation on a roll-to-roll process—a critical step in getting the project to the pilot scale. While a much higher technology readiness level is needed to reach manufacturing, the team is confident of BatMan’s capability to make an impact on actual battery manufacturing at scale.

According to Finegan, there aren’t any major engineering challenges that prevent going to scale, and convincing manufacturers to adapt to the new process is a soft challenge.

“We've derisked it. We've demonstrated that the cost is competitive. The performance benefits are huge. And it's scalable to roll-to-roll,” Finegan said. “It's now being considered by several companies. I think it’s just a matter of time,” he said.

Giving an exact timeline for when the BatMan project could see real-world application in the market is not easy to say. However, the required engineering could, in theory, be achieved in a commercial product within 1 to 2 years of a company’s commitment to implementing it, according to Finegan.

Charging forward

The BatMan project quadrupled the capacity accepted within 15 minutes compared to the baseline, and the accelerated throughput of batteries during manufacturing has cost reduction benefits.

Infographic: Battery Upgrades Unlocked

The team is also looking into the potential for extending the cycle life of the battery by introducing local wells of excess electrolyte in the electrode and other possibilities for moving beyond the current state-of-the-art technology.

“We’re also interested in understanding if this laser ablation can be beneficial in different or newer battery chemistries—whether it would still be lithium ion, but using different materials for the electrodes, or even looking at things that are not lithium-ion batteries,” Finegan said.

Sarah Alburakeh is strategic content editor.