Energy Storage Moves to New Heights: Part 2

Energy Storage Moves to New Heights: Part 2

Part One of “Energy Storage Moves to New Heights” explored the background of the Max Bögl Wind’s innovative turbine system. This section delves into how they’re made and operate.

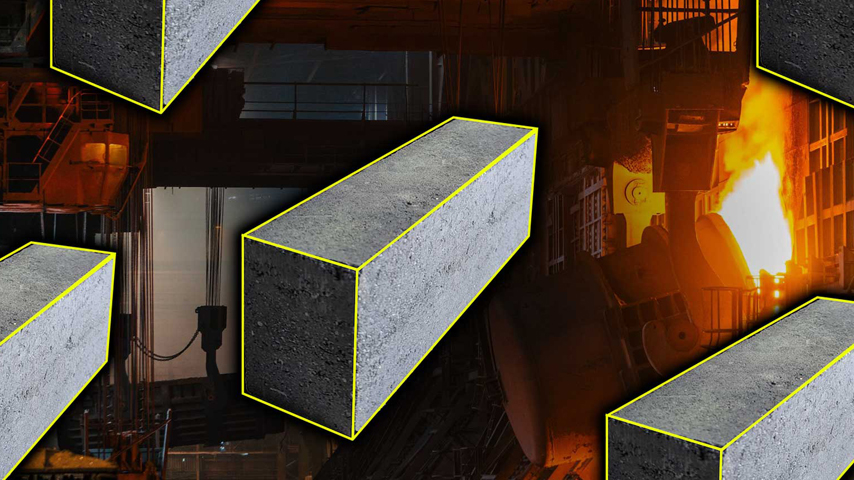

The contractor fitted precast-concrete segments on top of a poured-in-place foundation connected to the tanks. The segments are machined to one-tenth of a millimeter with a milling machine to allow them to be stacked directly on top of each other using dry joints. At Gaildorf, they are bolted together and post-tensioned. A steel tube was then installed to top off the tower for the turbine connection. The design and technique allows construction to be completed quickly, within one week, company officials say.

Batteries are becoming a more economic and reliable solution for smoothing delivery of renewable energy to the grid, or providing frequency regulation. But pumped storage is a better option under the right circumstances, Kleineheismann says. She notes it is proven technology with a very long operating history and a design life of at least 50 years. But this option requires at least a 200-meter fall height from the upper reservoir to the lower reservoir for efficient operation, she says.

The wind turbines now are operating and feeding power directly to the national grid. The system is also designed for peak shaving, provide frequency regulation and contribute to the spot market. When finished and operating later this year, the storage component will have a response time within 30 seconds, Kleineheismann says. The reservoirs have a storage capacity of 70 MWh of power. While batteries have a faster response time, they have a shorter lifetime, present issues for recycling, and have a higher carbon footprint, she claims.

More for You: Catch up on the latest Environmental Engineering at ASME.org.

The new design elements for the pumped storage scheme helped it qualify for 7.3 million Euros in grants from The German Federal Ministry for the Environment, Nature Conservation, Construction and Reactor Safety. Total project costs have been reported at $81 million, but the firm will not confirm the amount. Research and development costs for the pilot will not be reflected in the cost of future projects, but capital expenditures for the water battery will be 300 to 400 Euros per kWh, Kleineheisman says. Incorporating what becomes a water reservoir into the tower foundation on a hill or mountain eliminates the construction of a standard reservoir, a costly major earthmoving project that generally draws environmental opposition. The power plant is fitted with reversible Francis turbines.

Instead of specifying steel pipe for the penstocks, the firm moved to high-pressure, 2-meter-diameter polyethylene pipe, a first for a pump-storage project. The pipe was installed using a custom-built 100-meter-long platform that worked along a 6-to-10-meter-wide corridor on existing roads, reducing environmental impact.

Gaildorf is a pilot project for Bögl, which now is actively marketing the system globally. Kleineheismann says projects can be built modularly in increments of 16, 24 or 32 MW, using turbines from a variety of manufacturers. For international projects or those in remote areas, the firm also provides a mobile factory to manufacture precast elements using local materials.