Making Sense of Sensors

Making Sense of Sensors

Sensors have radically changed how we understand and interact with our world, in real time. Sensors provide us with data for just about every aspect of our day-to-day lives. Rapid improvements in technology, including miniaturization and advanced microprocessor integration, make the range of sensor applications almost endless.

“For example, today you can carry a small sensor around your finger, with all the processing and algorithms self-contained,” says Allen Nejah, a mechanical and aerospace engineer with SunMan Engineering, a San Jose, Calif.-based company that designs and develops sensor applications for a variety of industries and businesses.“Only less than a decade ago, this same functionality involved multiple circuit boards, fans, and the specific sensing hardware to go with it.”

These rapid advances in sensor technology (coupled with dropping costs) are motivating companies to deploy sensor technologies to gather important data for product development, strategic planning, and market performance. New mechanical processes, for example, have enabled the development of new sensing materials that can be micro-fabricated and integrated into complementary metal-oxide semiconductors (CMOS chips).

“The design of the sensors themselves requires the work of mechanical engineers,” says Nejah.“We feel that the continued advance of sensor technology will require innovative contributions from mechanical engineers in the future.”

Applications Abound

Sensors allow the detection of data and key performance metrics that can be analyzed to improve product quality or operational efficiency. Smart sensors wirelessly transmit this data in real time to other equipment for storage and analysis. Limits can be set that trip an alarm when certain thresholds are indicated, or action is required. Sensor applications include:

- Structural monitoring of bridges, dams, and other structures

- Traffic patterns

- Environmental monitoring and detection

- Energy consumption and management

- Manufacturing efficiency and performance

- Agricultural conditions

- E-health

Smart sensors are used throughout the manufacturing industry to monitor operational parameters and machine conditions, improve safety, optimize maintenance, and reduce downtime.

“As technology progresses, more and more sensors will be equipped with digital communications technology,” comments Mark Langridge, director of sales and marketing for packaging, food, and beverage and consumer goods for SICK, a Minneapolis-based manufacturer of sensors and safety systems. “These sensors will also become more powerful and intelligent, allowing them to gather and process even more data, and to communicate this information to not only the control system, but also to other platforms.”

Smart sensors are starting to transform the healthcare industry by providing a wealth of personalized data from patients in their homes, leading to a surge in e-health products and services. These sensor-based devices can help patients manage chronic conditions on a daily basis, or provide early warnings for emerging medical problems.

For example, miniature, high-resolution sensors worn by patients help them better track and manage chronic conditions like diabetes and heart disease. “Advanced analytical engines could monitor signals from multiple sensor types and provide personalized, real-time recommendations for individual patients,” states Chad Bouton, a researcher with Battelle, an independent R&D organization, in a recent article on mddionline.com.“Smart sensors could use predictive analytics to alert doctors to developing signs of kidney failure, stroke, heart failure, and other medical crises before adverse events occur. Injectable biosensors could be used to monitor cancer patients in remission for biomarkers that could indicate a recurrence.”

Sensors also enable the monitoring of sports performance. These can range from simple armband devices that measure pulse and heart rate to highly sophisticated devices that measure more than 1,000 data points per second. For example, Catapult Sports in Australia makes a sensor device that analyzes metrics such as acceleration, deceleration, distance, and speed to measure “player load.” This value is then used to determine if a practice or event is too hard, the reps too many, or if the potential for injury is looming.

Moving Forward

New advances in engineering and data analytics are resulting in smaller, more functional, and more powerful sensors. Some of these are made especially to withstand extreme temperatures, pressure, humidity, chemicals, and mechanic vibration that are typically found in harsh working conditions.“Continued advances in miniaturization will expand the potential uses of medical sensors and improve biocompatibility for long-term monitoring,” says Bouton. “Extreme miniaturization may soon allow development of tiny devices that can be injected into the bloodstream to monitor kidney or thyroid function, or neural implants that can eavesdrop on an individual nerve.”

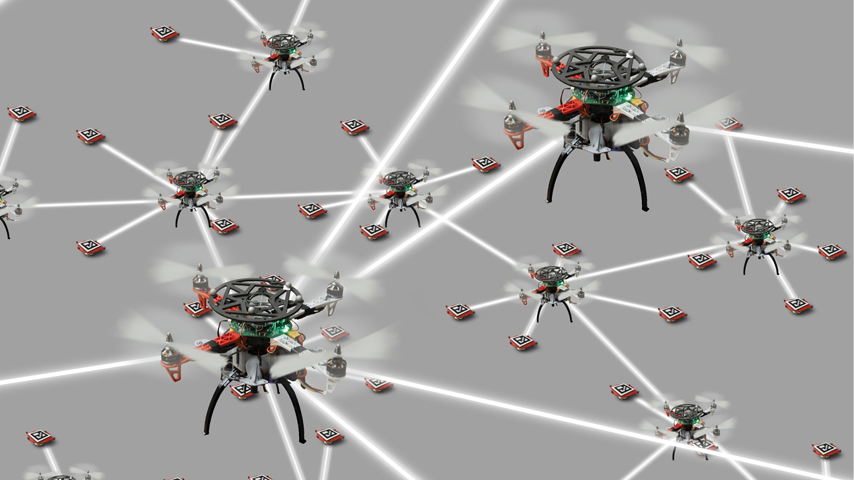

As sensors become smarter, and the computation of data expands dramatically, there will be a vast need for the effective analysis, storage, and retrieval of mass amounts of data—which leads us to the Internet of Things.

“Within a few years, we will have to talk in brontobyteswhen we discuss data coming from sensors,” says Mark van Rijmenam, founder of Datafloq, a company that helps companies develop big-data strategies. “The Internet of Things, or machine-to-machine (M2M) communication, connects billions of devices with each other and thereby generates an unfathomable amount of data. In 2020, 40 percent of all data in the world will be M2M data. This data, of course, has to be processed, stored, analyzed, and visualized to have any meaning and to drive business improvement.”

Rijmenam notes that the Internet of Things provides “limitless possibilities, when everything is connected to everything. “Our planet Earth will become a smart planet, where every item is instrumented, intelligent, and interconnected. The potential is enormousand the use cases are vast.”

It’s truly amazing how fast all the industries have adopted sensors, including industries which would never have used this kind of technology in the past,” concludes Nejah.“The possibilities really are endless when you add real-time sensing to the world.”

Mark Crawford is an independent writer.

Only less than a decade ago, this same functionality involved multiple circuit boards, fans, and the specific sensing hardware to go with it. Allen Nejah, SunMan Engineering