Mechanical Engineering Career Trends for Manufacturing

Mechanical Engineering Career Trends for Manufacturing

Mechanical engineering job growth is expected to continue into 2025 as these professionals lean into innovative technologies to advance traditional manufacturing processes as design and production.

Whether you’re a newly graduated mechanical engineer or a seasoned professional, keeping up with industry trends is essential. One foundational trend that MEs can continue to rely on is healthy job growth. According to the U.S. Bureau of Labor Statistics (BLS), while the average rate of growth across all occupations is 4 percent, for MEs the projected percent change in employment from 2023 to 2033 is 11 percent and “much faster than average.”

And recent graduates and engineers with less than five years of experience are in the best position to take advantage of the current circumstances, according to Jim Gerlock, an executive recruitment specialist with Addison Group. According to him, these individuals hold “foundational, technical knowledge” that is required in a variety of fields, but especially in manufacturing.

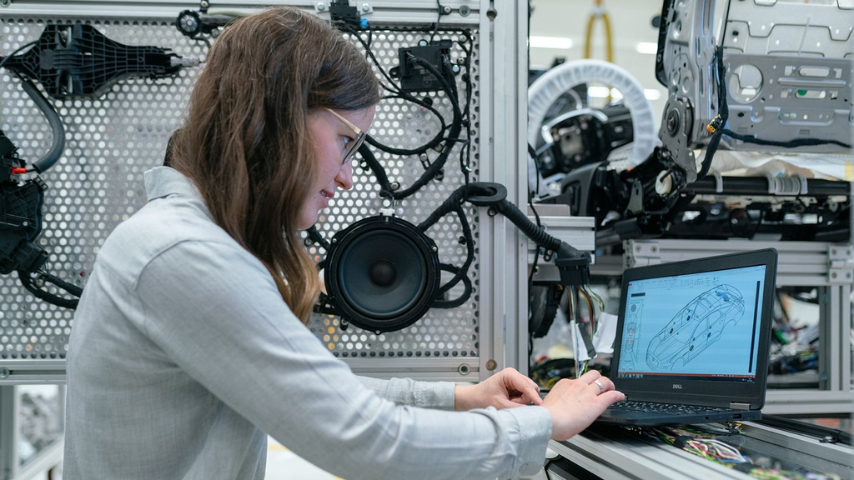

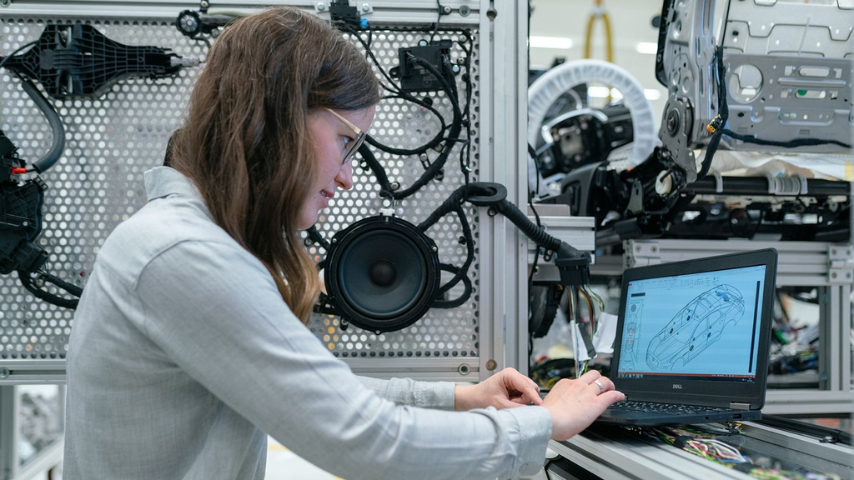

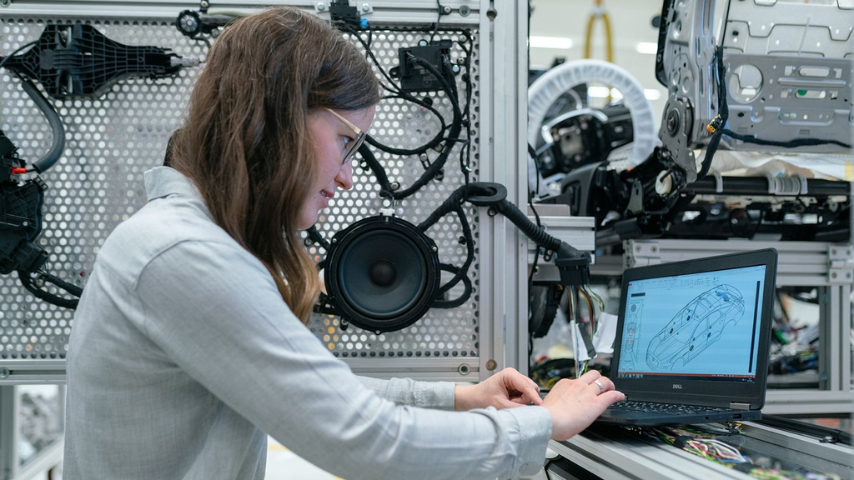

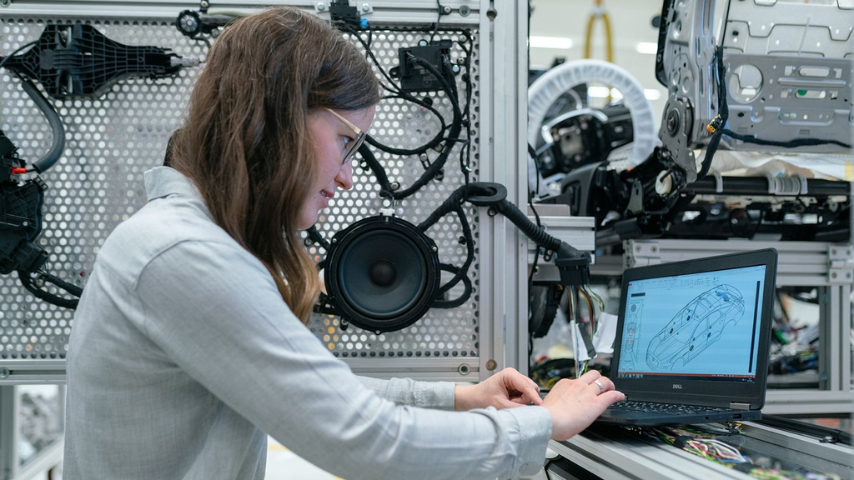

Among the factors contributing to the demand for MEs, projected to reach nearly 20,000 opening each year over the same decade, is their ability to deliver innovative solutions in varying industries. When working for automotive and aerospace manufacturers, for example, MEs are those who promote advances in design and production such as automation, 3D printing, robotics, artificial intelligence, and machine learning.

Discover the Benefits of ASME Membership

And manufacturing is coming back in the U.S., Gerlock said of both light and heavy industry. The “2025 Workforce Planning Guide” covers trends, strategies, and geographic and role-based salary data. It includes the national manufacturing average salary for COO ($252,924), VP of manufacturing ($192,521), and Director of Manufacturing ($146,929). Beyond leadership, Gerlock said, “The market is looking at professionals that know systems.” He looked at the application of software and technology to mechanical engineering processes as the key to success in this area for MEs.

Manufacturing is expected to remain the largest employer of MEs continuing into 2025, accounting for a substantial 45.4 percent of the profession. Among the top manufacturers employing engineers, according to Forbes, are companies that include Rolls-Royce, Airbus, and Caterpillar. Such projections are understandable as smart manufacturing looks toward systems to integrate the Internet of Things (IoT) and big data to deliver critical efficiencies and data-driven production.

Gerlock concluded that despite the continued need for engineers, MEs need to prepare now for the coming changes. By no means an exhaustive list, the following are seven areas that will continue to trend on the manufacturing floor, with three bonus areas that MEs should continue to be aware of.

According to Forbes, generative artificial intelligence (genAI) will continue to reduce the time it takes to design and develop products.The reliability and scalability of traditional automation tools and methods will continue to allow decision-makers to balance AI innovation with digital and robotic process automation platforms. AI models will support “bursts of insight and efficiency,” Forbes reported.

The importance of computer-aided engineering (CAE) tools remains a top concern for engineers as they get more efficient at virtual testing, design iteration, and the overall reduction of time and costs associated with prototyping.One of the trends for 2025 is the further integration of artificial intelligence and machine learning (AI/ML) within CAD/CAM systems. This strategy is to further optimize tool paths, suggest machining strategies, and predict potential issues before they occur. Finally, as systems become more sophisticated, the need for interactive and virtual training and education will help professionals keep up with tool advancements, reported Ency.

Sustainable Internet of Things (IoT) solutions will take center stage in 2025. Manufacturers will strive to leverage the data of connected devices to ensure optimum use and minimum waste of energy and other resources, reported techHindustan. Some obvious outcomes are better energy and water management, better tracking of goods during storage and transportation, and smart energy grids.

Refined integration of AI/ML with 3D printing will become better when it comes to precision, material waste, and speed. AI/ML will be generating data in real time, allowing printers to better adjust parameters such as temperature, speed, and material flow. This ensures consistent, high-quality results, explained Objective3D. The result will be greater consistency and reduced downtime.

Because of a perfect storm of computer vision and deep neural networks, robots are finally able to navigate, make decisions, and adapt to changing conditions. Change has been incremental, but as finding workers becomes more problematic, robots with AI-driven algorithms will move into place and enhance efficiency and reduce errors, reported Analytic Insight.

Startups are continuously developing new methods and improving conventional methods such as carbon-vapor deposition (CVD) to synthesize carbon nanomaterials, reported StartUs Insights. These carbon nanostructures offer higher mechanical strength, chemical stability, durability, and flexibility compared to conventional materials. Some carbon nanomaterials include graphene, carbon dots, and carbon nanotubes (CNTs) will find further use in 2025 in electronics, tissue engineering, and textiles.

Three more bonus trends that are traditional but are gathering steam of late are advanced predictive and control engineering, how advanced materials respond and wear, and finally how humans best interact with machines.

Mechanical engineers will be called upon to predict and control advanced, interconnected, and often autonomous machines. In the automotive industry, for example, engineers are responsible for designing systems that prevent overheating and maintain efficiency. Now, cheaper processing power and sensors, combined with enhanced communications infrastructures and the integration of technologies, are opening new opportunities in systems and control.

Understanding how materials respond to forces and wear is a critical aspect of mechanical engineering that remains important. In aerospace, MEs will ensure that materials used in designs can withstand environmental conditions and loads. They will be the experts when it comes to durability, corrosion, and withstanding extreme conditions, all while adhering to industry standards. Advances include new alloys, foams, and micro lattices.

Innovation will take into consideration ergonomics and worker safety. But beyond removing eye and muscle strain, technology will soon allow us to “talk” to machines using natural language. Recent advances in image and video understanding will also enable machines to understand human gestures—removing keyboards, levers, and buttons. Beyond head movements and small hand gestures, recent advances reported show machines that can decode facial expressions, reported Forbes.

Cathy Cecere is membership content program manager.

And recent graduates and engineers with less than five years of experience are in the best position to take advantage of the current circumstances, according to Jim Gerlock, an executive recruitment specialist with Addison Group. According to him, these individuals hold “foundational, technical knowledge” that is required in a variety of fields, but especially in manufacturing.

Among the factors contributing to the demand for MEs, projected to reach nearly 20,000 opening each year over the same decade, is their ability to deliver innovative solutions in varying industries. When working for automotive and aerospace manufacturers, for example, MEs are those who promote advances in design and production such as automation, 3D printing, robotics, artificial intelligence, and machine learning.

Discover the Benefits of ASME Membership

And manufacturing is coming back in the U.S., Gerlock said of both light and heavy industry. The “2025 Workforce Planning Guide” covers trends, strategies, and geographic and role-based salary data. It includes the national manufacturing average salary for COO ($252,924), VP of manufacturing ($192,521), and Director of Manufacturing ($146,929). Beyond leadership, Gerlock said, “The market is looking at professionals that know systems.” He looked at the application of software and technology to mechanical engineering processes as the key to success in this area for MEs.

Manufacturing is expected to remain the largest employer of MEs continuing into 2025, accounting for a substantial 45.4 percent of the profession. Among the top manufacturers employing engineers, according to Forbes, are companies that include Rolls-Royce, Airbus, and Caterpillar. Such projections are understandable as smart manufacturing looks toward systems to integrate the Internet of Things (IoT) and big data to deliver critical efficiencies and data-driven production.

Gerlock concluded that despite the continued need for engineers, MEs need to prepare now for the coming changes. By no means an exhaustive list, the following are seven areas that will continue to trend on the manufacturing floor, with three bonus areas that MEs should continue to be aware of.

Automation

According to Forbes, generative artificial intelligence (genAI) will continue to reduce the time it takes to design and develop products.The reliability and scalability of traditional automation tools and methods will continue to allow decision-makers to balance AI innovation with digital and robotic process automation platforms. AI models will support “bursts of insight and efficiency,” Forbes reported.

Computer-aided engineering

The importance of computer-aided engineering (CAE) tools remains a top concern for engineers as they get more efficient at virtual testing, design iteration, and the overall reduction of time and costs associated with prototyping.One of the trends for 2025 is the further integration of artificial intelligence and machine learning (AI/ML) within CAD/CAM systems. This strategy is to further optimize tool paths, suggest machining strategies, and predict potential issues before they occur. Finally, as systems become more sophisticated, the need for interactive and virtual training and education will help professionals keep up with tool advancements, reported Ency.

Internet of Things

Sustainable Internet of Things (IoT) solutions will take center stage in 2025. Manufacturers will strive to leverage the data of connected devices to ensure optimum use and minimum waste of energy and other resources, reported techHindustan. Some obvious outcomes are better energy and water management, better tracking of goods during storage and transportation, and smart energy grids.

3D printing

Refined integration of AI/ML with 3D printing will become better when it comes to precision, material waste, and speed. AI/ML will be generating data in real time, allowing printers to better adjust parameters such as temperature, speed, and material flow. This ensures consistent, high-quality results, explained Objective3D. The result will be greater consistency and reduced downtime.

Robotics

Because of a perfect storm of computer vision and deep neural networks, robots are finally able to navigate, make decisions, and adapt to changing conditions. Change has been incremental, but as finding workers becomes more problematic, robots with AI-driven algorithms will move into place and enhance efficiency and reduce errors, reported Analytic Insight.

Nanotechnology

Startups are continuously developing new methods and improving conventional methods such as carbon-vapor deposition (CVD) to synthesize carbon nanomaterials, reported StartUs Insights. These carbon nanostructures offer higher mechanical strength, chemical stability, durability, and flexibility compared to conventional materials. Some carbon nanomaterials include graphene, carbon dots, and carbon nanotubes (CNTs) will find further use in 2025 in electronics, tissue engineering, and textiles.

Three more trends

Three more bonus trends that are traditional but are gathering steam of late are advanced predictive and control engineering, how advanced materials respond and wear, and finally how humans best interact with machines.

Predictive and control engineering

Mechanical engineers will be called upon to predict and control advanced, interconnected, and often autonomous machines. In the automotive industry, for example, engineers are responsible for designing systems that prevent overheating and maintain efficiency. Now, cheaper processing power and sensors, combined with enhanced communications infrastructures and the integration of technologies, are opening new opportunities in systems and control.

Material response and wear

Understanding how materials respond to forces and wear is a critical aspect of mechanical engineering that remains important. In aerospace, MEs will ensure that materials used in designs can withstand environmental conditions and loads. They will be the experts when it comes to durability, corrosion, and withstanding extreme conditions, all while adhering to industry standards. Advances include new alloys, foams, and micro lattices.

Human-machine interaction

Innovation will take into consideration ergonomics and worker safety. But beyond removing eye and muscle strain, technology will soon allow us to “talk” to machines using natural language. Recent advances in image and video understanding will also enable machines to understand human gestures—removing keyboards, levers, and buttons. Beyond head movements and small hand gestures, recent advances reported show machines that can decode facial expressions, reported Forbes.Cathy Cecere is membership content program manager.