Bacteria-Powered Solar Cells Are Ideal for Cloudy Climates

Bacteria-Powered Solar Cells Are Ideal for Cloudy Climates

Solar energy is a wonderful renewable energy, as long as a steady supply of photons is needed to make it all work. Sunny climates are best. In regions where cloudy skies are common, such as parts of Canada and Northern Europe, adopting solar power can be problematic and expensive, especially for large-scale applications.

Now researchers at the University of British Columbia (UBC), led by chemical and biological engineering professor Vikramaditya G. Yadav, have discovered an affordable way to build a bacteria-powered, biogenic solar cell that works well in cloudy environments.

In a conventional or inorganic solar cell, crystalline silicon serves as the electron generator. In a biogenic solar cell, the material that is excited by light is biological in origin. In both types of cells, the electron generator is part of the anode. Electrons move from the anode to cathode to produce the electric current. In the UBC solar cell, the biogenic material is the pigment lycopene, which is best known for giving tomatoes their red color.

Listen to ASME TechCast Episode 2 to hear how engineers close the communication gap with non-engineers.

The team was struck by this idea when they were developing bacterial “mini-factories” to produce large quantities of lycopene for use in nutraceuticals. After genetically engineering bacteria to produce large quantities of lycopene, they noticed that when the lycopene was stored in transparent glass bottles, the pigment steadily degraded over time. Some research by the students revealed that the lycopene molecule is highly excitable by light and degrades immediately upon exposure to light.

One of his students then asked, “Really? Lycopene degrades that easily upon exposure to light? What would happen if we put it in a solar cell?”

“That’s the question that got us interested in developing dye-sensitized solar cells,” Yadav says.

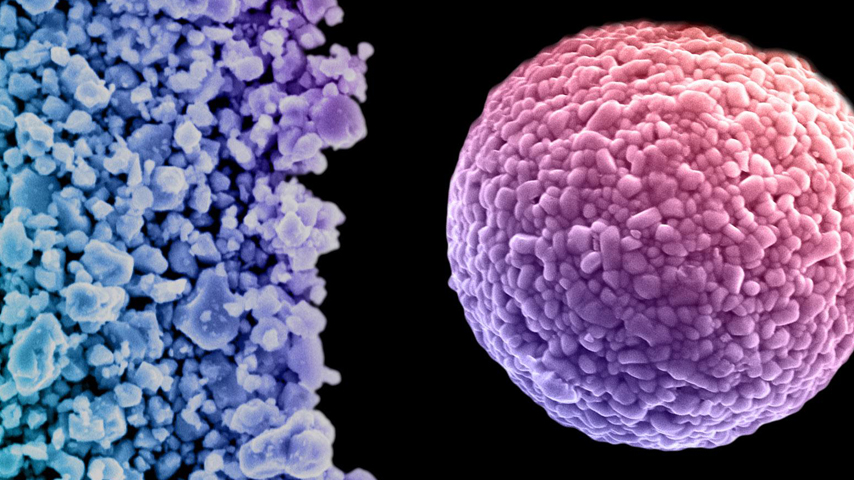

A diagram of the anode of a solar cell, comprised of biogenic material made of lycopene-producing bacteria (the orange orbs) and coated with titania nanoparticles. Image: Vikramaditya Yadav

How It Works

When light falls on lycopene, it degrades and releases electrons. Yadav and his team wondered if the rate of degradation was enough to generate a usable current.

Their first step consisted of the genetic modification of a strain of E. coli bacteria to produce large amounts ofphotosensitive lycopene. The E. coli commonly used in the biotechnology industry is quite different from the strains that typically cause diseases, and are incapable of competing with natural, unmodified strains. Therefore, “any fears of accidental release of potentially disease-causing bacteria are misplaced,” Yadav says.

The bacteria was then coated with TiO2nanoparticles via a tryptophan mediated supramolecular interface and applied to a glass surface, creating a semiconductor. The titanium coating makes the bacteria highly conductive and allows the electrons to move more easily from the anode to the cathode.

The semiconductor was then deployed as an anode in an I−/I3−-based dyesensitized solar cell. When exposed to light, the bacteria released photons that moved via the titanium to the cathode, creating a current density of 0.686 milliamps per square centimeter—an improvement on the 0.362 achieved by other biogenic prototypes.

“In fact, we recorded the highest current density for any biogenic solar cell,” Yadav says.

Future Possibilities

Yadav’s solar cell is a successful proof-of-concept for the fabrication of genetically customizable biogenic materials for photovoltaic applications, according to the team’s recent paper. Because the bacteria-powered cell works well under low light conditions, it may be an ideal choice as a light source in the future for mining, deep-sea exploration, and other low-light environments.

A major drawback to this technology is that the bacteria eventually dies and the solar cell needs to be replaced. Yadav hopes to discover a cell design that does not kill the bacteria. “If we can do this, we can achieve dye production over an extended time period, which will stretch the usable life of these cells,” he says.

As a first-generation device, the prototype needs significant improvements and optimization before it can reach the levels of silicon solar cells that can deliver about 25 times the current density of the bacterial-based solar cell.

Yadav’s team is already working on improving the current solar cell, including alternative chemistries for covering the bacteria and boosting the bacteria’s electrical potential. He also expects sizable gains in efficiency through the use of more sophisticated fabrication techniques such as ordered deposition of the biogenic material, use of platinum as the counter electrode, better matching of electrolytes, and use of more light-sensitive dyes.

Although it is a bioengineering project thus far, Yadav believes mechanical engineers have a significant role to play in “the steps that come immediately after ours—how best to assemble the complete solar cell to ensure higher current densities and greater durability, as well as reducing the cost of storing the electrical energy so produced.”

More than anything, Yadav says the project taught him the value of cross-collaboration across multiple scientific fields, including biochemical engineering, material science, and electrochemistry.

“This would not have been possible if we didn’t have people from different disciplines talking to one another and asking basic questions,” he says.

Mark Crawford is an independent technology writer.

Read More: Raspberry Pi’s Eben Upton on Design and Innovation A Prosthetic ArmBangs the Drums Smart BandageDoes It All

In fact, we recorded the highest current density for any biogenic solar cell.Prof. Vikramaditya G. Yadav, University of British Columbia