Building the Versatile Test Reactor with Digital Engineering Tools

Building the Versatile Test Reactor with Digital Engineering Tools

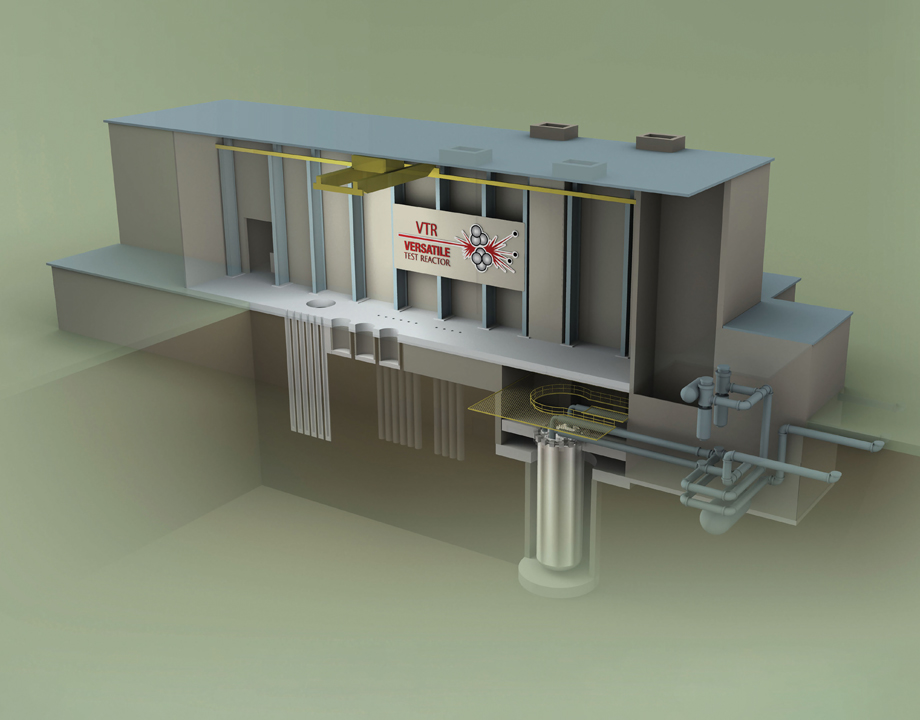

Researchers are using digital engineering to sequence construction of the Versatile Test Reactor, which is being developed to produce fast neutrons to study material properties. Image: INL

Like most major infrastructure construction, nuclear energy projects are subject to delays and cost overruns. Specifically, new conventional light water reactors have struggled because design errors are discovered late in the process, and construction is often delayed for the redesign and regulatory approval of the retrofit. Those delays create often unacceptable financial risk for would-be private investors.

Now, researchers at Idaho National Laboratory have adapted digital engineering technology to help build the Department of Energy’s proposed Versatile Test Reactor (VTR). It is expected that developing VTR via digital engineering will significantly reduce risk by organizing all the project’s data and models in a centralized, interactive system that guides the complex project from inception, through design and construction, and into operations.

Using digital information management systems, VTR engineers will integrate engineering drawings, cost estimates, schedules, and more along a “common thread,” said Chris Ritter, VTR’s digital engineering technical lead. “Instead of having documents, you have a database that links everything together.”

A design change to one component—say, a coolant pipe—will propagate through the system. Near real-time updates on the cloud allow VTR’s team of national laboratory, industry, and university partners to access the information quickly and securely to make the necessary changes to the rest of the project.

By some estimates, correcting problems during conceptual design costs a thousand times less than fixing the same problem during operations. “A lot of the problems can be avoided if we practice in the digital world first,” said Kemal Pasamehmetoglu, executive director of the Versatile Test Reactor. “With digital engineering, we have a very quick way of knowing how one change influences everything else.”

When Ritter and Pasamehmetoglu began exploring the idea, they found numerous examples of high-tech industries—including aerospace and automotive—that use digital engineering to optimize their schedules and costs.

For example, Minneapolis-based Mortenson Construction pioneered its own version of digital engineering in the 1990s and has used it to build megaprojects from baseball stadiums to hospitals to art museums. The company estimates that digital engineering has reduced construction schedules by an average of 32 days per project and resulted in a 25 percent increase in productivity.

Recommended for You: Digital Engineering During COVID-19

Other companies that have deployed digital engineering solutions have seen similar productivity gains. GE estimates use of digital engineering has saved the company more than $1.05 billion, and the U.S. Air Force is relying on this technology for designing and building its next generation of fighter aircraft.

Ritter and his colleagues hope that using digital engineering on the Versatile Test Reactor will serve as an example that helps hasten the development of the next generation of nuclear reactors as well.

What makes the Versatile Test Reactor challenging to design and build is that it’s not a conventional power reactor but a one-of-a-kind science machine. VTR will be a vital research tool for the existing fleet of power reactors and the more than 40 U.S. companies currently developing advanced reactors for future domestic and global clean energy markets. To validate their designs and remain competitive, many of these companies have identified a need for a testing environment with fast neutrons.

The Versatile Test Reactor is optimized to create fast neutrons—roughly 100 times the neutron flux of a water-moderated reactor—in order to test how well fuels, materials, safety technologies, and sensors endure in a power reactor core. Bombarding these materials with high-intensity neutrons in a test reactor helps researchers understand how to make them stronger and longer-lived. Just a few months of high-intensity neutron bombardment in a test reactor can mimic years of neutron radiation in a power reactor core.

VTR will also help advance technologies related to space exploration.

Upon its completion, VTR will be the most advanced fast neutron source in the world. “We haven’t done something like this for many decades,” Pasamehmetoglu said.

Join our Digital Engineering Conversations

Since VTR will be both one of a kind and the first reactor built using fully integrated digital engineering in the U.S., Ritter has relied on partners with expertise in information management, integrated modeling, and 3D modeling to help create INL’s digital engineering platform. Among the private-sector partners are General Electric Hitachi and Bechtel National, which have been advancing the design and cost estimates for the VTR based on GEH’s PRISM technology.

TerraPower, a nuclear reactor design company in Bellevue, Wash., has developed something it calls the Advanced Reactor Modeling Interface to integrate modeling codes rather than running modeling and simulations independently; this digital engineering tool is expected to increase the efficiency of experimental design.

Universities are also contributing to the effort. North Carolina State University in Raleigh developed a method to automate 3D modeling, which has allowed the VTR team to automate seismic and pipe-stress analysis, an industry first that will boost accuracy and efficiency. And Virginia Commonwealth University in Richmond helped develop a Requirements Information Management tool to capture requirements, risks, and tests in a fully integrated database to understand the full impact of changes and automatically generate documentation.

The fledgling digital engineering system developed by the VTR team has already paid dividends. The researchers were able to sequence the construction of the plant, answering questions such as where to put electrical connections, when to connect the primary cooling system to the secondary cooling system, and where to place the heat exchangers.

Sequencing the VTR’s construction will ultimately help coordinate the workforce and the equipment that goes to the construction site, helping keep construction teams on task and working efficiently. Dialing in answers to these questions also helped the VTR team pass a critical review milestone.

“We were able to put a very aggressive schedule together, which is unprecedented for this type of project,” Pasamehmetoglu said. “We were told by the external boards reviewing the cost and schedule estimates that we have things under control despite the schedule.”

Ritter’s geographically dispersed, multiorganizational team was also able to develop a 3D model of VTR only four months into the project. The engineers worked with desktop tools to build their models. They then committed the models to the cloud-based database, complete with digital tags that allow designers and engineers to see relationships between the 3D model and other pieces of the system.

Relying on readily available engineering models means that sectional drawings and fly-throughs are produced quickly and with a high level of detail and accuracy.

“We are not going to exchange design changes through PowerPoint slides,” Pasamehmetoglu said. “They do it in the digital environment directly into the design platform Chris put together. Anybody who wants to see that design change can see it right away. Especially since we are a team spread across the United States, that makes it a lot easier. Within 24 hours, everyone is seeing design changes for the 2D and 3D models.”

The construction sequence and the 3D models are just two of any number of digital engineering information threads that will prove valuable once the construction phase of VTR is complete.

“We can use digital engineering through construction and then turn it over to operations so they can use it to simulate fuel replacement or whatever else they need,” Pasamehmetoglu said. “Everything is going to be documented on one platform.”

All the documentation, models, and data created during the digital engineering phase will also enable researchers to create a so-called “digital twin” of the Versatile Test Reactor. A digital twin is a computer emulation of the reactor, a highly detailed virtual duplicate informed by data from advanced sensors and smart systems located throughout the real-world VTR. Such a model will permit INL researchers to create monitoring and control modules, enhanced by artificial intelligence, that enable smart functionalities such as autonomous operation, flexible operation, and predictive maintenance.

Listen to a Podcast: Lockheed Martin’s Digital Twin Journey

“We’ll have essential physics models connected,” said Ritter. “We’ll have all the 3D models connected. We’ll connect everything from the original design all the way to the operational data in near real time.”

Given the relative dearth of new reactor construction in the U.S., no one to date has applied digital engineering to the development and design of nuclear reactors. By creating such a system for the Versatile Test Reactor, the researchers hope it will serve as a kind of template for using the technology for new power reactor design and construction.

“Building VTR will give the rest of the nuclear industry a real ‘kick the tires’ demonstration of this important digital engineering technology,” Pasamehmetoglu said. “The big question is, ‘Why haven’t we been doing something like this for many decades?’”

Cory Hatch is a science writer for Idaho National Laboratory.

REGISTER TODAY FOR ASME’S DIGITAL TWIN SUMMIT

Now, researchers at Idaho National Laboratory have adapted digital engineering technology to help build the Department of Energy’s proposed Versatile Test Reactor (VTR). It is expected that developing VTR via digital engineering will significantly reduce risk by organizing all the project’s data and models in a centralized, interactive system that guides the complex project from inception, through design and construction, and into operations.

Using digital information management systems, VTR engineers will integrate engineering drawings, cost estimates, schedules, and more along a “common thread,” said Chris Ritter, VTR’s digital engineering technical lead. “Instead of having documents, you have a database that links everything together.”

A design change to one component—say, a coolant pipe—will propagate through the system. Near real-time updates on the cloud allow VTR’s team of national laboratory, industry, and university partners to access the information quickly and securely to make the necessary changes to the rest of the project.

By some estimates, correcting problems during conceptual design costs a thousand times less than fixing the same problem during operations. “A lot of the problems can be avoided if we practice in the digital world first,” said Kemal Pasamehmetoglu, executive director of the Versatile Test Reactor. “With digital engineering, we have a very quick way of knowing how one change influences everything else.”

When Ritter and Pasamehmetoglu began exploring the idea, they found numerous examples of high-tech industries—including aerospace and automotive—that use digital engineering to optimize their schedules and costs.

For example, Minneapolis-based Mortenson Construction pioneered its own version of digital engineering in the 1990s and has used it to build megaprojects from baseball stadiums to hospitals to art museums. The company estimates that digital engineering has reduced construction schedules by an average of 32 days per project and resulted in a 25 percent increase in productivity.

Recommended for You: Digital Engineering During COVID-19

Other companies that have deployed digital engineering solutions have seen similar productivity gains. GE estimates use of digital engineering has saved the company more than $1.05 billion, and the U.S. Air Force is relying on this technology for designing and building its next generation of fighter aircraft.

Ritter and his colleagues hope that using digital engineering on the Versatile Test Reactor will serve as an example that helps hasten the development of the next generation of nuclear reactors as well.

Fast Neutrons

What makes the Versatile Test Reactor challenging to design and build is that it’s not a conventional power reactor but a one-of-a-kind science machine. VTR will be a vital research tool for the existing fleet of power reactors and the more than 40 U.S. companies currently developing advanced reactors for future domestic and global clean energy markets. To validate their designs and remain competitive, many of these companies have identified a need for a testing environment with fast neutrons.

The Versatile Test Reactor is optimized to create fast neutrons—roughly 100 times the neutron flux of a water-moderated reactor—in order to test how well fuels, materials, safety technologies, and sensors endure in a power reactor core. Bombarding these materials with high-intensity neutrons in a test reactor helps researchers understand how to make them stronger and longer-lived. Just a few months of high-intensity neutron bombardment in a test reactor can mimic years of neutron radiation in a power reactor core.

VTR will also help advance technologies related to space exploration.

Upon its completion, VTR will be the most advanced fast neutron source in the world. “We haven’t done something like this for many decades,” Pasamehmetoglu said.

Join our Digital Engineering Conversations

Since VTR will be both one of a kind and the first reactor built using fully integrated digital engineering in the U.S., Ritter has relied on partners with expertise in information management, integrated modeling, and 3D modeling to help create INL’s digital engineering platform. Among the private-sector partners are General Electric Hitachi and Bechtel National, which have been advancing the design and cost estimates for the VTR based on GEH’s PRISM technology.

TerraPower, a nuclear reactor design company in Bellevue, Wash., has developed something it calls the Advanced Reactor Modeling Interface to integrate modeling codes rather than running modeling and simulations independently; this digital engineering tool is expected to increase the efficiency of experimental design.

Universities are also contributing to the effort. North Carolina State University in Raleigh developed a method to automate 3D modeling, which has allowed the VTR team to automate seismic and pipe-stress analysis, an industry first that will boost accuracy and efficiency. And Virginia Commonwealth University in Richmond helped develop a Requirements Information Management tool to capture requirements, risks, and tests in a fully integrated database to understand the full impact of changes and automatically generate documentation.

Connect Everything

The fledgling digital engineering system developed by the VTR team has already paid dividends. The researchers were able to sequence the construction of the plant, answering questions such as where to put electrical connections, when to connect the primary cooling system to the secondary cooling system, and where to place the heat exchangers.

Sequencing the VTR’s construction will ultimately help coordinate the workforce and the equipment that goes to the construction site, helping keep construction teams on task and working efficiently. Dialing in answers to these questions also helped the VTR team pass a critical review milestone.

“We were able to put a very aggressive schedule together, which is unprecedented for this type of project,” Pasamehmetoglu said. “We were told by the external boards reviewing the cost and schedule estimates that we have things under control despite the schedule.”

Ritter’s geographically dispersed, multiorganizational team was also able to develop a 3D model of VTR only four months into the project. The engineers worked with desktop tools to build their models. They then committed the models to the cloud-based database, complete with digital tags that allow designers and engineers to see relationships between the 3D model and other pieces of the system.

Relying on readily available engineering models means that sectional drawings and fly-throughs are produced quickly and with a high level of detail and accuracy.

“We are not going to exchange design changes through PowerPoint slides,” Pasamehmetoglu said. “They do it in the digital environment directly into the design platform Chris put together. Anybody who wants to see that design change can see it right away. Especially since we are a team spread across the United States, that makes it a lot easier. Within 24 hours, everyone is seeing design changes for the 2D and 3D models.”

The construction sequence and the 3D models are just two of any number of digital engineering information threads that will prove valuable once the construction phase of VTR is complete.

“We can use digital engineering through construction and then turn it over to operations so they can use it to simulate fuel replacement or whatever else they need,” Pasamehmetoglu said. “Everything is going to be documented on one platform.”

All the documentation, models, and data created during the digital engineering phase will also enable researchers to create a so-called “digital twin” of the Versatile Test Reactor. A digital twin is a computer emulation of the reactor, a highly detailed virtual duplicate informed by data from advanced sensors and smart systems located throughout the real-world VTR. Such a model will permit INL researchers to create monitoring and control modules, enhanced by artificial intelligence, that enable smart functionalities such as autonomous operation, flexible operation, and predictive maintenance.

Listen to a Podcast: Lockheed Martin’s Digital Twin Journey

“We’ll have essential physics models connected,” said Ritter. “We’ll have all the 3D models connected. We’ll connect everything from the original design all the way to the operational data in near real time.”

Given the relative dearth of new reactor construction in the U.S., no one to date has applied digital engineering to the development and design of nuclear reactors. By creating such a system for the Versatile Test Reactor, the researchers hope it will serve as a kind of template for using the technology for new power reactor design and construction.

“Building VTR will give the rest of the nuclear industry a real ‘kick the tires’ demonstration of this important digital engineering technology,” Pasamehmetoglu said. “The big question is, ‘Why haven’t we been doing something like this for many decades?’”

Cory Hatch is a science writer for Idaho National Laboratory.

REGISTER TODAY FOR ASME’S DIGITAL TWIN SUMMIT