Floating Pyramids Could Make for Cheaper Wind Power

Floating Pyramids Could Make for Cheaper Wind Power

Standard piles driven into the seabed require specialized ships. A new design rides the waves to make offshore wind farms easier to build.

Sometimes the answer to a large, complex problem is floating right in front of us. That certainly could be the case for offshore wind power. Companies working to build offshore wind farms have been bedeviled by costs involved in anchoring skyscraper-size towers on the seabed and designing active controls for steering the blades into the best position to capture power.

According to engineers at a Boston-based startup, the solution may be as simple as building pyramid-shaped support structures that float in the water and passively orient themselves to face the wind. Anchored by a few mooring lines, much like a buoy in the sea, these turbines can withstand harsh weather and huge waves, making them an ideal alternative to the fixed bottom monopile wind turbines that have been implemented thus far.

“With this design, we set out to embrace the inevitable motion of being offshore,” explained Vin Loccisano, chief operating officer at T-Omega Wind. “We designed the entire structure with the assumption that it is going to move, it’s going to ride over waves, and we will just have to engineer our way out of any problems that ensue. We found that those problems are quite manageable.”

Due to the strong and steady winds found over ocean waters, experts consider offshore wind to be a promising source of renewable power. According to the Global Wind Energy Council, more than 64.3 gigawatts of global offshore wind capacity was in operation by the end of 2022, accounting for 7.1 percent of global wind power installation.

Recognizing the need for engineering enhancements to offshore wind, Andy Myers and Jim Papadopoulos—who met in 2011 as engineering professors at Northeastern University—began patenting their floating design in 2018 and launched T-Omega in 2020.

Become an ASME member

The main benefit of a floating turbine is that it takes out massive amounts of steel from the system. The floating turbine can also function in much deeper depths, making it versatile for countries that want to implement offshore wind but don’t have the appropriate depths at their coastlines.

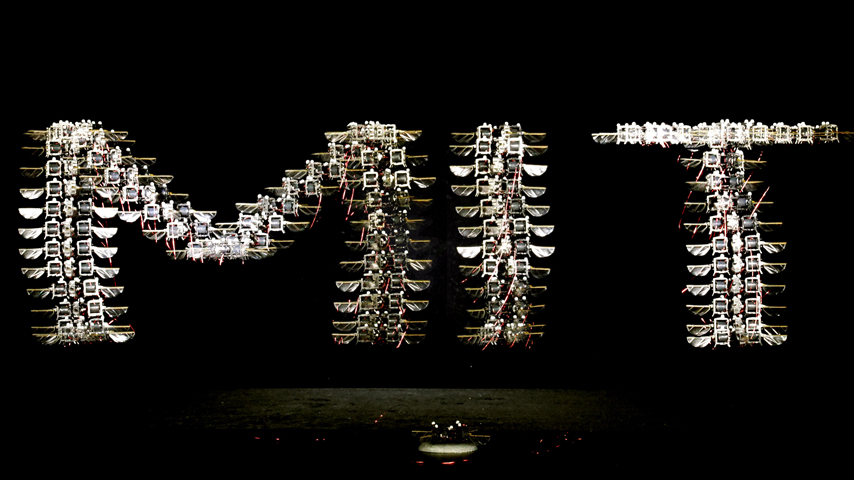

The T-Omega design was built “from the water up” and includes a three-bladed, horizontal axis rotor that spins between two upwind and two downwind legs. The configuration allows the axle to be held at both ends like a bicycle wheel.

There is no active yaw, such as with traditional turbines, but rather the turbine is anchored with a mooring line that provides a small radius to respond to the conditions of the sea. As the wind direction changes, the turbine passively swings to align with the wind.

Each floating pyramid can support turbines capable of generating up to 20 megawatts. They can be clustered together to form wind farms.

As Loccisano explained, the design relies on existing technology to make this a scalable solution.

“There’s no magic in our blades,” he said. “There’s no magic in our generator, or control system, or software. We’re making sound business and engineering decisions to buck the trend.”

One factor contributing to the high cost of offshore wind is the availability of specialized ships to transport the large pieces from port to the wind farm site and serve as a platform for installing the towers and turbines. There are few of these ships in existence, and most of them are barred from operating in U.S. waters due to Federal law, so the time and cost to construct offshore wind farms has escalated in recent years.

By contrast, floating wind turbines such as T-Omega’s can be built completely in port and towed to the wind farm site, a simple task that does not need a specialized ship. And because the floating turbines are easier to install, they are also easier to fix. When something goes awry, a team can go out to retrieve the floating vessel, swap it out with a new one, and bring the faulty one to port for maintenance.

Learn New Skills: Introduction to Computational Fluid Dynamics

This tow and swap protocol also reduces human risk tremendously and saves developers and insurance companies from added costs.

Also, compared to traditional turbines that might be out of commission for up to seven days, the floating turbines can be swapped out within an afternoon.

“Downtime is a real issue for existing turbines,” Loccisano said. “Every time they’re not producing power, the companies are being penalized by the customer. So having a spare turbine in port to rapidly swap and replace whatever may be down makes financial sense in these wind farm settings.”

“Our first real-world test was exciting,” said Dave Forbes, T-Omega’s chief commercial officer. “It validated the stability of the structure.”

“We do not have the baggage of legacy engineering choices,” Loccisano said. “We have an idealized project with the lowest possible costs. None of this is revolutionary in its individual aspects, but when you put it all together, it’s remarkable.”

Cassandra Kelly is a technology writer in Columbus, Ohio.

According to engineers at a Boston-based startup, the solution may be as simple as building pyramid-shaped support structures that float in the water and passively orient themselves to face the wind. Anchored by a few mooring lines, much like a buoy in the sea, these turbines can withstand harsh weather and huge waves, making them an ideal alternative to the fixed bottom monopile wind turbines that have been implemented thus far.

“With this design, we set out to embrace the inevitable motion of being offshore,” explained Vin Loccisano, chief operating officer at T-Omega Wind. “We designed the entire structure with the assumption that it is going to move, it’s going to ride over waves, and we will just have to engineer our way out of any problems that ensue. We found that those problems are quite manageable.”

Due to the strong and steady winds found over ocean waters, experts consider offshore wind to be a promising source of renewable power. According to the Global Wind Energy Council, more than 64.3 gigawatts of global offshore wind capacity was in operation by the end of 2022, accounting for 7.1 percent of global wind power installation.

Easier to build

The potential for growth is stymied by high costs. Offshore turbines existing today are prohibitively expensive to install and maintain. The monopole design, with a rigid, steel tower pounded into and anchored on the seabed, is only viable in waters up to 180 feet deep and poses many different challenges to the ecosystem and the companies that maintain them.Recognizing the need for engineering enhancements to offshore wind, Andy Myers and Jim Papadopoulos—who met in 2011 as engineering professors at Northeastern University—began patenting their floating design in 2018 and launched T-Omega in 2020.

Become an ASME member

The main benefit of a floating turbine is that it takes out massive amounts of steel from the system. The floating turbine can also function in much deeper depths, making it versatile for countries that want to implement offshore wind but don’t have the appropriate depths at their coastlines.

The T-Omega design was built “from the water up” and includes a three-bladed, horizontal axis rotor that spins between two upwind and two downwind legs. The configuration allows the axle to be held at both ends like a bicycle wheel.

There is no active yaw, such as with traditional turbines, but rather the turbine is anchored with a mooring line that provides a small radius to respond to the conditions of the sea. As the wind direction changes, the turbine passively swings to align with the wind.

Each floating pyramid can support turbines capable of generating up to 20 megawatts. They can be clustered together to form wind farms.

As Loccisano explained, the design relies on existing technology to make this a scalable solution.

“There’s no magic in our blades,” he said. “There’s no magic in our generator, or control system, or software. We’re making sound business and engineering decisions to buck the trend.”

One factor contributing to the high cost of offshore wind is the availability of specialized ships to transport the large pieces from port to the wind farm site and serve as a platform for installing the towers and turbines. There are few of these ships in existence, and most of them are barred from operating in U.S. waters due to Federal law, so the time and cost to construct offshore wind farms has escalated in recent years.

By contrast, floating wind turbines such as T-Omega’s can be built completely in port and towed to the wind farm site, a simple task that does not need a specialized ship. And because the floating turbines are easier to install, they are also easier to fix. When something goes awry, a team can go out to retrieve the floating vessel, swap it out with a new one, and bring the faulty one to port for maintenance.

Learn New Skills: Introduction to Computational Fluid Dynamics

This tow and swap protocol also reduces human risk tremendously and saves developers and insurance companies from added costs.

Also, compared to traditional turbines that might be out of commission for up to seven days, the floating turbines can be swapped out within an afternoon.

“Downtime is a real issue for existing turbines,” Loccisano said. “Every time they’re not producing power, the companies are being penalized by the customer. So having a spare turbine in port to rapidly swap and replace whatever may be down makes financial sense in these wind farm settings.”

Scale-model success

The turbines showed success in early digital twin simulations. In December 2023, the company tested a one-sixteenth-scale prototype in New Bedford, Mass. The model demonstrated that the design could withstand extreme weather, surviving 6-foot waves, which are the scale equivalent to 96-foot monster waves.“Our first real-world test was exciting,” said Dave Forbes, T-Omega’s chief commercial officer. “It validated the stability of the structure.”

“We do not have the baggage of legacy engineering choices,” Loccisano said. “We have an idealized project with the lowest possible costs. None of this is revolutionary in its individual aspects, but when you put it all together, it’s remarkable.”

Cassandra Kelly is a technology writer in Columbus, Ohio.