Medical Training with 3D Printing

Medical Training with 3D Printing

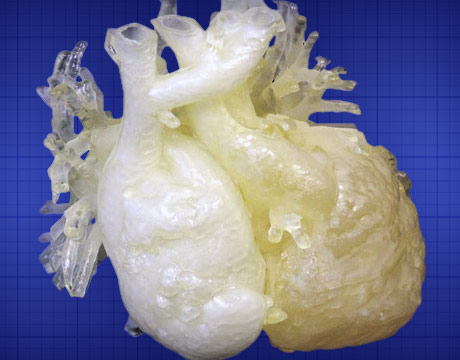

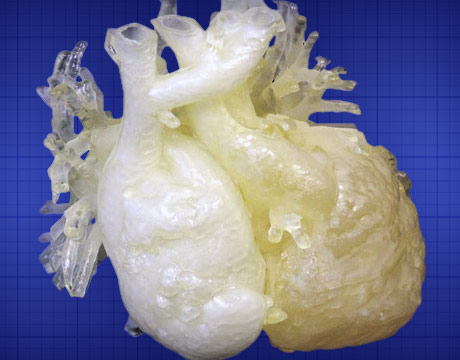

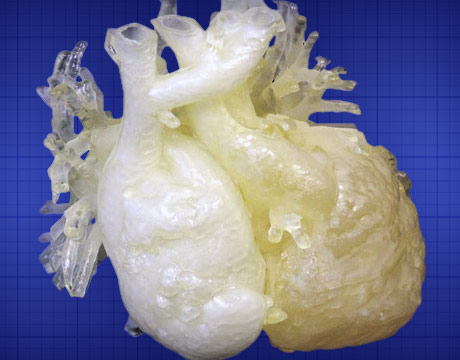

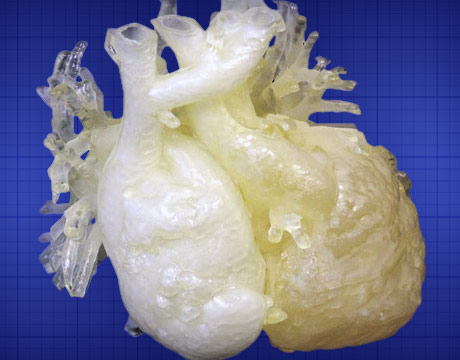

The 3D printed heart model is used in the preoperative process to study a patient’s unique heart complexities. Image: Stratasys

Stories about the 3D printing of organs are appearing in the media more frequently, but many don’t realize how much of a factor 3D is becoming in the training of medical professionals. Printed charts and skeletons are proliferating in a way many feel can completely change the way doctors learn and even explain procedures. It’s also becoming a more common part of preparation for surgeons. Here is a look at how it’s helping training and pre-planning.

Before Surgery

Scott Rader, head of medical solutions at 3D printing company Stratasys, likens it to being an athlete, saying you don’t put someone up against a major league pitcher without practice. But the ballgame he’s talking about is surgery.

The 3D process here begins with a medical scan and that data is translated into printing. “Under surgical preplanning, it’s to take the image files that we can generate in either two dimensions or three dimensions with CT or MRI and then create as realistic phantoms as we can that take advantage of the natural operative evolution.” He further explains thatthe process involvessynthesizing multiple senses to help the surgeon consider what they will do in surgery.

Rader says a great advantage of 3D printing is that it can use false color or false transparency to help physicians think about aspects such as what is neural tissue, what is a vein versus an artery, and so forth. It can enhance the visualization needed. “Here, every time we go into the operating room as physicians, it’s challenging to really understand what you’re gong to find when you open up that patient,” he says. “3D printing can break down those barriers and do it more than just [with] visual clues. We can actually reproduce that anatomy so that you feel what the tissue feels like, whether it’s hard tissue [or] soft tissue and you can actually dissect those models.”

Surgical Training

Surgically speaking, throughout the history of training doctors, the most common method has been peer-to-peer or mentor-to-peer, using such elements as animal models and cadavers, says Rader. 3D printing changes this relationship because now, for example, you have the ability to replicate a patient with a complicated problem.

Dr. Jason Koh, an orthopedic surgeon, also thinks that’s a benefit ofthe 3D model for the doctor and also the patient. “3D printing allows you to not be stuck with this one type and to possibly help in understanding what you’re dealing with,” he says. “You can also better explain the situation to the patient using these tools when they can hold something like this while you talk. They can see the situation. It can sometimes help ease a patient’s mind when they also have a better understanding of what’s going on.”

Rader definitely sees areas of promise as well. “We’re at a point today where we can very, very closely simulate soft and hard tissues and where we can extend this technology in the future is to add wetness to the tissue,” he says, also mentioning conductivity to simulate utilization of energy devices, such as radio frequency energy or ultrasound devices.

Eric Butterman is an independent writer.

Learn more about the latest technologies in 3D printing at ASME’s AM3D 2015.

3D printing allows you to not be stuck with this one type and to possibly help in understanding what you’re dealing withDr. Jason Koh, orthopedic surgeon