Nanoscale Device Harvests Electricity Through Evaporation

Nanoscale Device Harvests Electricity Through Evaporation

Researchers have created a nanoscale device that harvests electricity from evaporating fluids across a wide range of salinity conditions.

Evaporation-driven fluid flow in porous or nanostructured materials is showing potential for renewable energy generation by converting thermal energy into electrical energy via an electrokinetic pathway.

So far, this hydrovoltaic (HV) effect has only been demonstrated in bulk porous systems, making it harder to understand the physical phenomena that control these reactions. As a result, fundamental questions remain regarding the interfacial interactions that define these HV devices—especially the geometrical and chemical characteristics of the system. These limiting factors, when combined with the lack of modeling tools, restrict the performance and application range for HV technology.

To narrow this knowledge gap, Giulia Tagliabue, an assistant professor at the Laboratory of Nanoscience for Energy Technology in Switzerland, and doctoral student Tarique Anwar undertook a series of experiments and multiphysics modeling to characterize fluid flows, ion flows, and electrostatic effects due to solid-liquid interactions with the goal of improving performance of future HV devices.

Their research is detailed in “Salinity-dependent interfacial phenomena toward hydrovoltaic device optimization,” recently published in Device.

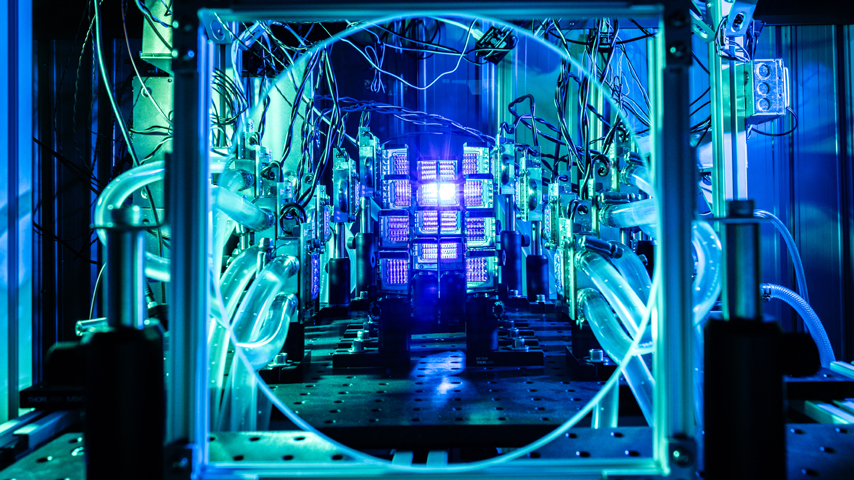

The team’s prototype nanoscale device represents a breakthrough with vast untapped energy potential.

Discover the Benefits of ASME Membership

A crucial obstacle was constructing an experimental platform with precise control over the geometrical size of the nanostructures. This level of control was essential for establishing direct connections between specific interfacial interactions and the overall performance of the macroscopic device, including its voltage and current output. “To overcome this challenge, we developed a thorough comprehension of nanofluidics and energy conversion processes, as well as master advanced fabrication techniques,” Anwar said.

The resulting device represents the first hydrovoltaic application of a technique called nanosphere colloidal lithography, which allowed them to create a hexagonal network of precisely spaced silicon nanopillars. Spaces between the nanopillars created the perfect channels for evaporating fluid samples. Those spaces could also be finely tuned to better understand the effects of fluid confinement and the solid/liquid contact area.

Most fluidic systems that contain saline solutions have an equal number of positive and negative ions. However, when the liquid is confined to a nanochannel, only ions with a polarity opposite to that of the surface charge will remain. “This means that if you allow liquid to flow through the nanochannel, you will generate current and voltages,” explained Anwar.

Also, as the fluid ion concentration increases, so does the surface charge of the nanodevice. As a result, the larger fluid channels can be used when working with higher-concentration fluids. This makes it easier to fabricate devices for use with tap or seawater, as opposed to only purified water.

You Might Also Enjoy: Metamaterials in Concrete Produce Electricity

By creating structural imbalances in the device's geometry, “we can generate a voltage contribution solely from the electrostatic effect,” Anwar noted. “Even with very low evaporation rates, this effect can produce a significant voltage [>0.1 V] in our system.” This process can be enhanced by manipulating the surface charge distribution using chemical or physical methods to create spatial non-uniformity. Additionally, the performance of p-type silicon nanopillars is comparable to that of previously reported n-type silicon, indicating the potential for expanding material options and designing heterostructures with maximized asymmetry along the nanochannel.

“Beyond electrokinetic parameters, we have shown that structural asymmetries generate an electrostatic potential, augmenting HV performance,” Tagliabue said. “For molar-level concentrations, we provide evidence of ion adsorption and charge inversion for several monovalent cations, enabling HV devices to operate even at such high concentrations. Overall, we can uniquely demonstrate a high-power density output of 8 μW/cm2 at 0.1 meters. Thus, our work paves the way for the broader applicability of HV systems across salinity scales.”

The rapid advancement of these devices has the potential to impact various fields significantly. They can be utilized for energy harvesting in self-powered portable systems, providing a sustainable and reliable power source for a wide range of applications. These devices can also be employed as highly sensitive sensing devices, enabling precise and accurate monitoring in various environments.

“They can be integrated as hybrid devices, combining their capabilities with other functionalities such as clean water production and electricity generation, opening up new possibilities for addressing pressing global challenges,” Anwar said.

Mark Crawford is a technology writer in Corrales, N.M.

So far, this hydrovoltaic (HV) effect has only been demonstrated in bulk porous systems, making it harder to understand the physical phenomena that control these reactions. As a result, fundamental questions remain regarding the interfacial interactions that define these HV devices—especially the geometrical and chemical characteristics of the system. These limiting factors, when combined with the lack of modeling tools, restrict the performance and application range for HV technology.

To narrow this knowledge gap, Giulia Tagliabue, an assistant professor at the Laboratory of Nanoscience for Energy Technology in Switzerland, and doctoral student Tarique Anwar undertook a series of experiments and multiphysics modeling to characterize fluid flows, ion flows, and electrostatic effects due to solid-liquid interactions with the goal of improving performance of future HV devices.

Their research is detailed in “Salinity-dependent interfacial phenomena toward hydrovoltaic device optimization,” recently published in Device.

Experimental approach

Tagliabue and Anwar aimed to build a controlled experimental platform that lies between nanofluidic studies of individual nanochannels and macroscale porous device testing. “This idea is built on our lab research interests, where we develop various highly controlled nanostructured functional materials for different energy-related applications,” Anwar said.The team’s prototype nanoscale device represents a breakthrough with vast untapped energy potential.

Discover the Benefits of ASME Membership

A crucial obstacle was constructing an experimental platform with precise control over the geometrical size of the nanostructures. This level of control was essential for establishing direct connections between specific interfacial interactions and the overall performance of the macroscopic device, including its voltage and current output. “To overcome this challenge, we developed a thorough comprehension of nanofluidics and energy conversion processes, as well as master advanced fabrication techniques,” Anwar said.

The resulting device represents the first hydrovoltaic application of a technique called nanosphere colloidal lithography, which allowed them to create a hexagonal network of precisely spaced silicon nanopillars. Spaces between the nanopillars created the perfect channels for evaporating fluid samples. Those spaces could also be finely tuned to better understand the effects of fluid confinement and the solid/liquid contact area.

Most fluidic systems that contain saline solutions have an equal number of positive and negative ions. However, when the liquid is confined to a nanochannel, only ions with a polarity opposite to that of the surface charge will remain. “This means that if you allow liquid to flow through the nanochannel, you will generate current and voltages,” explained Anwar.

Also, as the fluid ion concentration increases, so does the surface charge of the nanodevice. As a result, the larger fluid channels can be used when working with higher-concentration fluids. This makes it easier to fabricate devices for use with tap or seawater, as opposed to only purified water.

You Might Also Enjoy: Metamaterials in Concrete Produce Electricity

By creating structural imbalances in the device's geometry, “we can generate a voltage contribution solely from the electrostatic effect,” Anwar noted. “Even with very low evaporation rates, this effect can produce a significant voltage [>0.1 V] in our system.” This process can be enhanced by manipulating the surface charge distribution using chemical or physical methods to create spatial non-uniformity. Additionally, the performance of p-type silicon nanopillars is comparable to that of previously reported n-type silicon, indicating the potential for expanding material options and designing heterostructures with maximized asymmetry along the nanochannel.

“Beyond electrokinetic parameters, we have shown that structural asymmetries generate an electrostatic potential, augmenting HV performance,” Tagliabue said. “For molar-level concentrations, we provide evidence of ion adsorption and charge inversion for several monovalent cations, enabling HV devices to operate even at such high concentrations. Overall, we can uniquely demonstrate a high-power density output of 8 μW/cm2 at 0.1 meters. Thus, our work paves the way for the broader applicability of HV systems across salinity scales.”

Moving forward

This research has uncovered how previously overlooked interfacial phenomena can enable hydrovoltaic devices to function across a wide range of salinity conditions found in natural and processed water. “This discovery challenges previous assumptions that purified water is essential for optimal device performance,” said Anwar. “The concentration-dependent surface charge, combined with the geometrical asymmetry in the device structures, results in peak output in high salinity conditions. These findings also show the adaptability of our devices to different environmental conditions.”The rapid advancement of these devices has the potential to impact various fields significantly. They can be utilized for energy harvesting in self-powered portable systems, providing a sustainable and reliable power source for a wide range of applications. These devices can also be employed as highly sensitive sensing devices, enabling precise and accurate monitoring in various environments.

“They can be integrated as hybrid devices, combining their capabilities with other functionalities such as clean water production and electricity generation, opening up new possibilities for addressing pressing global challenges,” Anwar said.

Mark Crawford is a technology writer in Corrales, N.M.