New Smart Farming System Minimizes Fertilizer Runoff

New Smart Farming System Minimizes Fertilizer Runoff

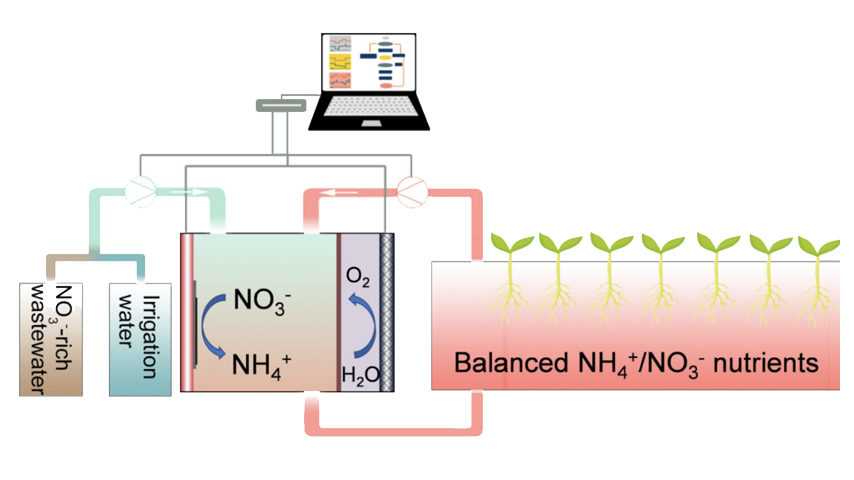

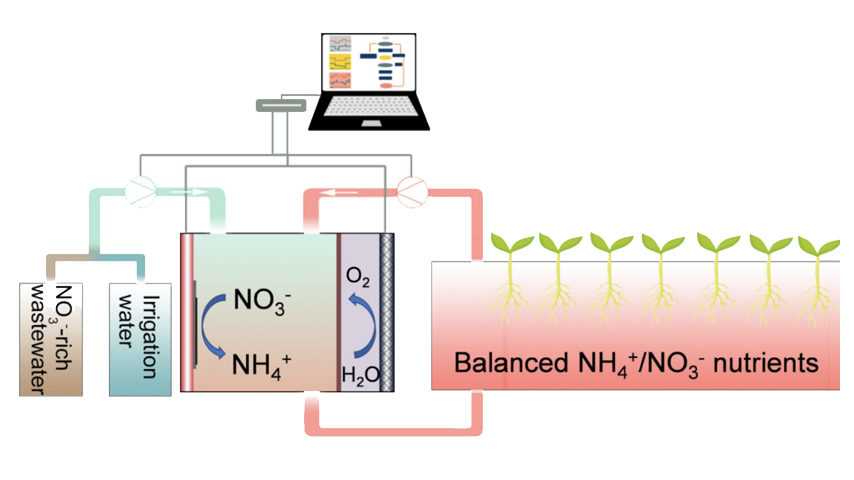

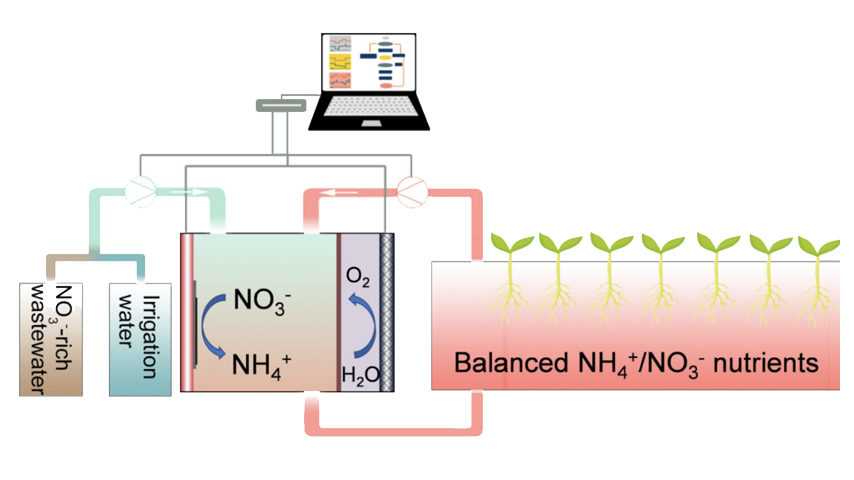

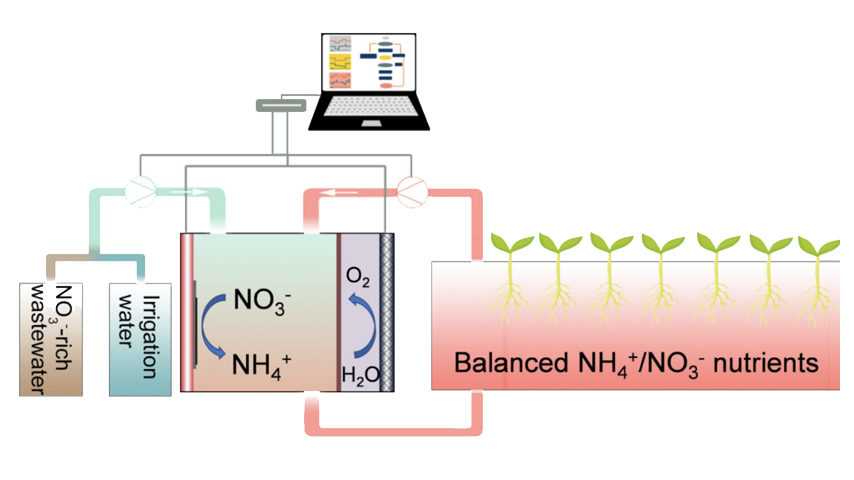

Researchers at the University of Texas at Austin have created a smart farming system that can capture and re-use common fertilizer pollutants.

The Environmental Protection Agency calls pollutants resulting from the overuse of fertilizers in agriculture “one of America’s most widespread, costly, and challenging environmental problems.” While fertilizers do help increase crop yields, the resulting chemical runoff can pollute both the water and the land over the long term.

“Fertilizer overuse is a huge problem in agriculture,” said Guihua Yu, a professor of materials science at the University of Texas at Austin’s Cockrell School of Engineering and Texas Materials Institute. “Overuse can cause land degradation which, over time, shrinks the amount of workable land. The pollution is also a big problem.”

Yu’s research team specializes in materials innovation to support more sustainable agricultural practices. A few years ago, he and his colleagues developed a nanomaterial electrocatalyst with the power to produce urea, a common fertilizer ingredient, from the nitrate wastewater produced by fertilizer. At that moment, Yu said, he and his team realized they could use new materials to do more to help manage agriculture’s growing nitrate run-off issue.

“We wanted to see if we could use similar materials to both produce urea onsite from the nitrate and monitor the nitrogen levels to distinguish the ratio of the usable form of nitrogen,” he said. “The material could then tell the system how to respond in a smart way, whether it’s in need of nitrogen to help the plants grow or if you already have an excessive nitrogen concentration that could be a problem. That was our starting point.”

Yu and colleagues developed a copper-based hydrogel as the foundation for a new smart farming system. The hydrogel captures excess nitrate waste from fertilizer run-off, transforming it into ammonia, similar to urea but more usable in fertilizing applications. The hydrogel also has the power to sense nitrogen levels in the soil, letting farmers know the right time to drain nitrate from the soil before it contaminates the water or soil in the immediate area.

“The gel provides a porous framework where you can load in metal ion centers,” Yu explained. “The material can sense the nitrogen level and provide instant feedback on whether the soil is in need of fertilizing. It can simultaneously control how much nitrate is flowing if there is already a lot in the soil. We are using these parts to create SSFS, the smart yet sustainable farming system where you have this monitoring, but you can also produce ammonia from the nitrate wastewater.”

Become a Member: How to Join ASME

When Yu and his team tested the SSFS in a proof-of-concept study, they found they were able to use the hydrogel for both sensing and ammonia production. They also discovered the system produced optimized wheat and rice plants with longer stalks and bigger leaves.

To date, the SFSS has only been tested in a laboratory setting, but Yu said he is looking forward to scaling it up for real-world use.

“It’s going to take more significant efforts in terms of understanding the different conditions needed to optimize the growth of different crops, as well as how to connect all of the system’s different parts,” he said. “But this kind of system is needed, and it can help the agriculture industry support more sustainable practices. We plan to test from this very small lab system to individual farming and then on to bigger, scaled up agricultural operations. I think we will learn a lot from the sensing information so we can build systems that are configured to support optimized growth.”

He added that there is also potential for the system to be used in industrial applications, to help manage nitrogen pollution in manufacturing operations.

More for You: Robotic Gripper's Soft Touch Promises Better Harvest

“You could use the hydrogel to monitor the industrial production of nitrate waste,” he said. “And then to produce urea or ammonia onsite. It’s important to understand that nitrate pollution is a problem in many industries and we need ways to better deal with this nitrate waste.”

Yu said that while the development of innovative materials is a key part of their success, he and his team’s close collaborations with agricultural experts is just as important.

“This kind of work requires integrating various expertise and that kind of multidisciplinary effort is what you need if you want to try and solve problems for grand challenges,” Yu said. “We learned a lot from talking to people in agriculture about nitrogen management, water use, and waste management. We had to learn those things so we could integrate them all in a system that could promote sustainability. We had a lot of good input from mechanical engineers and materials engineers. But without the input and opinions of the agricultural experts, we would not be able to make something that worked so well, and we wouldn’t be able to take the next steps to figure out how to build it for use at a larger scale.”

Kayt Sukel is a science and technology writer in Houston.

“Fertilizer overuse is a huge problem in agriculture,” said Guihua Yu, a professor of materials science at the University of Texas at Austin’s Cockrell School of Engineering and Texas Materials Institute. “Overuse can cause land degradation which, over time, shrinks the amount of workable land. The pollution is also a big problem.”

Yu’s research team specializes in materials innovation to support more sustainable agricultural practices. A few years ago, he and his colleagues developed a nanomaterial electrocatalyst with the power to produce urea, a common fertilizer ingredient, from the nitrate wastewater produced by fertilizer. At that moment, Yu said, he and his team realized they could use new materials to do more to help manage agriculture’s growing nitrate run-off issue.

“We wanted to see if we could use similar materials to both produce urea onsite from the nitrate and monitor the nitrogen levels to distinguish the ratio of the usable form of nitrogen,” he said. “The material could then tell the system how to respond in a smart way, whether it’s in need of nitrogen to help the plants grow or if you already have an excessive nitrogen concentration that could be a problem. That was our starting point.”

Yu and colleagues developed a copper-based hydrogel as the foundation for a new smart farming system. The hydrogel captures excess nitrate waste from fertilizer run-off, transforming it into ammonia, similar to urea but more usable in fertilizing applications. The hydrogel also has the power to sense nitrogen levels in the soil, letting farmers know the right time to drain nitrate from the soil before it contaminates the water or soil in the immediate area.

“The gel provides a porous framework where you can load in metal ion centers,” Yu explained. “The material can sense the nitrogen level and provide instant feedback on whether the soil is in need of fertilizing. It can simultaneously control how much nitrate is flowing if there is already a lot in the soil. We are using these parts to create SSFS, the smart yet sustainable farming system where you have this monitoring, but you can also produce ammonia from the nitrate wastewater.”

Become a Member: How to Join ASME

When Yu and his team tested the SSFS in a proof-of-concept study, they found they were able to use the hydrogel for both sensing and ammonia production. They also discovered the system produced optimized wheat and rice plants with longer stalks and bigger leaves.

To date, the SFSS has only been tested in a laboratory setting, but Yu said he is looking forward to scaling it up for real-world use.

“It’s going to take more significant efforts in terms of understanding the different conditions needed to optimize the growth of different crops, as well as how to connect all of the system’s different parts,” he said. “But this kind of system is needed, and it can help the agriculture industry support more sustainable practices. We plan to test from this very small lab system to individual farming and then on to bigger, scaled up agricultural operations. I think we will learn a lot from the sensing information so we can build systems that are configured to support optimized growth.”

He added that there is also potential for the system to be used in industrial applications, to help manage nitrogen pollution in manufacturing operations.

More for You: Robotic Gripper's Soft Touch Promises Better Harvest

“You could use the hydrogel to monitor the industrial production of nitrate waste,” he said. “And then to produce urea or ammonia onsite. It’s important to understand that nitrate pollution is a problem in many industries and we need ways to better deal with this nitrate waste.”

Yu said that while the development of innovative materials is a key part of their success, he and his team’s close collaborations with agricultural experts is just as important.

“This kind of work requires integrating various expertise and that kind of multidisciplinary effort is what you need if you want to try and solve problems for grand challenges,” Yu said. “We learned a lot from talking to people in agriculture about nitrogen management, water use, and waste management. We had to learn those things so we could integrate them all in a system that could promote sustainability. We had a lot of good input from mechanical engineers and materials engineers. But without the input and opinions of the agricultural experts, we would not be able to make something that worked so well, and we wouldn’t be able to take the next steps to figure out how to build it for use at a larger scale.”

Kayt Sukel is a science and technology writer in Houston.

Pulse of the Profession: Digital Transformation

The digital future of unified, cloud-based data and interconnected teams bring new possibilites.