Water-Free Cleaning of Solar Panels Saves Millions of Gallons of Water

Water-Free Cleaning of Solar Panels Saves Millions of Gallons of Water

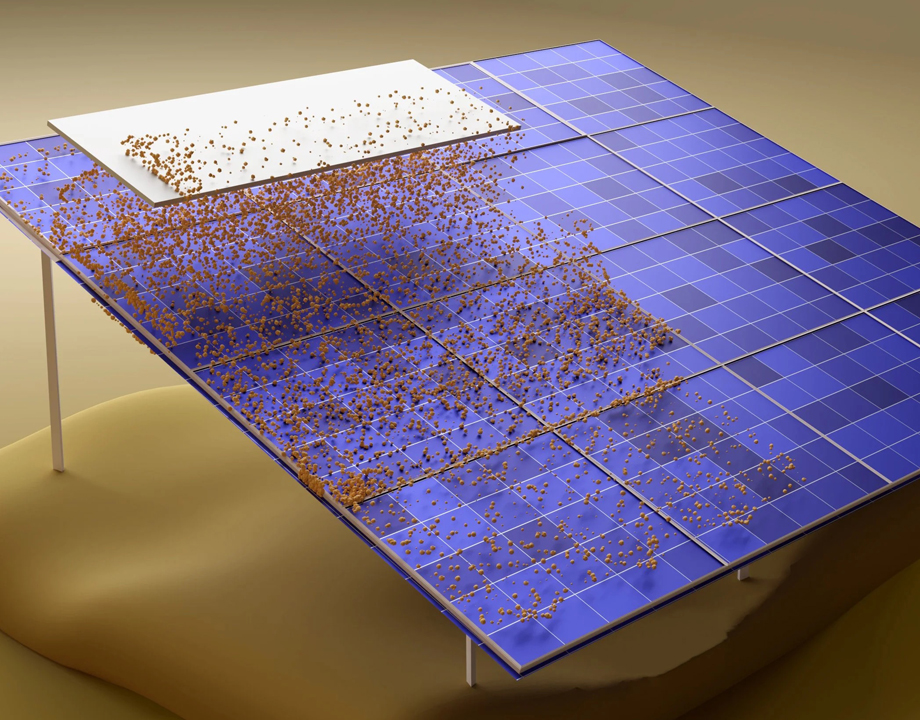

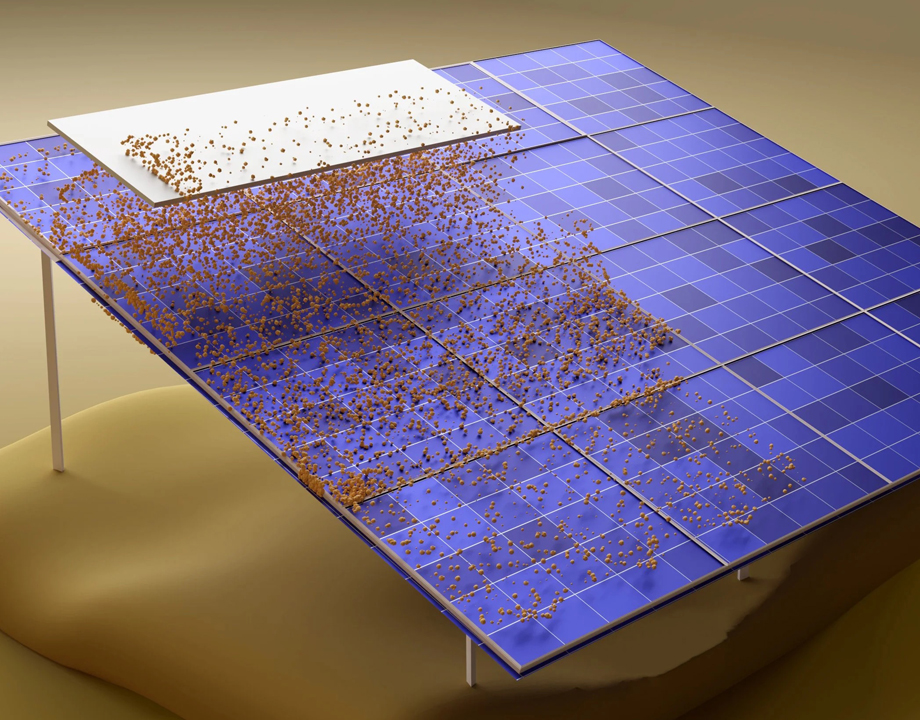

Mechanical engineers at MIT have developed a system that uses electrostatic induction to repel dust from photovoltaic solar panel surfaces. Image: MIT

Dust accumulation on photovoltaic solar panel surfaces can dramatically reduce output by as much as 30 percent in a single month if not cleaned, making regular cleaning essential for optimum performance. Standard cleaning requires significant amounts of water—more than 10 billion gallons of pure water are used every year to clean solar panels, enough drinking water for 2 million people.

Reducing the water footprint of the solar industry is important for making this renewable energy industry truly sustainable. Also, many solar farms are in desert areas, where dust accumulation is much more severe problem and water resources are very scarce. In addition, scrubbing techniques can irreversibly damage the panels (for example, high-pressure water jets that scratch the surface or leave behind spots and residues), which permanently reduces light transmission.

Thus the lack of an efficient system for maintaining dust-free solar panels remains a major obstacle to driving down the cost of solar energy and conserving water resources. To meet this challenge, a team of engineers at Massachusetts Institute of Technology has developed a waterless, no-contact cleaning method that relies on electrostatic induction to automatically remove dust from solar panels, or from the mirrors of solar thermal plants.

"The dust layer that accumulates on solar panels consists of small particles only a few tens of microns in diameter that cannot be easily removed due to Van der Waals forces and other surface forces,” said lead researcher Kripa K. Varanasi, professor of mechanical engineering at MIT. “We discovered that dust behaves more like a conductor and therefore electrostatic induction can be used to easily repel the dust from the surface. Dust particles, despite primarily consisting of insulating silica, can be electrostatically repelled from electrodes due to charge induction assisted by adsorbed moisture.”

Varanasi used a novel electrostatic approach to “actively charge” dust particles and then impart strong Coulombic force to repulse them from the surface.

The team determined dust particle charge by conducting Stokes experiments under an electrostatic field. “By considering electrostatic, van der Waals, and gravitational forces, we were able to define the threshold electric potential for particle removal,” said Varanasi.

More for You: 8 Hot Applications for Solar Power

Dust particles resting on the bottom electrode in a parallel plate setup were repelled from the surface on application of sufficient voltage. This occurs because of induction that charges the dust. When the same experiment was done with conductive iron particles or insulating Teflon particles, the team observed that dust particles qualitatively behaved more like iron, rather than Teflon.

To activate the system, a simple electrode such as a simple metal bar is passed just over the solar panel's surface, imparting an electrical charge to the dust particles. The team calculated an opposite voltage to apply that was strong enough to overcome the pull of gravity and adhesion forces. When this charge was applied to a transparent conductive layer just a few nanometers thick deposited on the glass covering of the solar panel, the particles were easily repelled.

The team also demonstrated the dust removal system worked well over a broad range of relative humidity, making it effective across a wide range of environments.

"As long as the ambient humidity is greater than 30 percent, you can remove almost all of the particles from the surface, but as humidity decreases, it becomes more difficult,” said Varanasi. The researchers then developed a lab-scale prototype that successfully demonstrated up to 95% recovery of lost power caused by the dust layer.

Editor's Pick: Leveraging Plastic Components for Solar-Powered Applications

Varanasi has proven that a simple electrostatic induction-based system is highly effective for removing the dust that accumulates on solar panels and recovering the energy that would have otherwise been blocked by the dust layer. The team is currently at work at streamlining the next model for testing and scale-up. For example, one possibility is a small electric motor, perhaps driven by electricity derived from a small portion the output from the panel itself, would drive a belt system to move the electrode from one end of the panel to the other, causing the dust to fall away.

Varanasi indicates there has been considerable interest in his technology from various companies including solar installations, utilities, and the private sector.

“We will be scaling up and piloting in real farms as we begin to commercialize the technology, which will likely also include robotic systems that can be used to implement the system on solar farms,” he said.

Mark Crawford is a science and technology writer in Corrales, N.M.

Reducing the water footprint of the solar industry is important for making this renewable energy industry truly sustainable. Also, many solar farms are in desert areas, where dust accumulation is much more severe problem and water resources are very scarce. In addition, scrubbing techniques can irreversibly damage the panels (for example, high-pressure water jets that scratch the surface or leave behind spots and residues), which permanently reduces light transmission.

Thus the lack of an efficient system for maintaining dust-free solar panels remains a major obstacle to driving down the cost of solar energy and conserving water resources. To meet this challenge, a team of engineers at Massachusetts Institute of Technology has developed a waterless, no-contact cleaning method that relies on electrostatic induction to automatically remove dust from solar panels, or from the mirrors of solar thermal plants.

"The dust layer that accumulates on solar panels consists of small particles only a few tens of microns in diameter that cannot be easily removed due to Van der Waals forces and other surface forces,” said lead researcher Kripa K. Varanasi, professor of mechanical engineering at MIT. “We discovered that dust behaves more like a conductor and therefore electrostatic induction can be used to easily repel the dust from the surface. Dust particles, despite primarily consisting of insulating silica, can be electrostatically repelled from electrodes due to charge induction assisted by adsorbed moisture.”

Varanasi used a novel electrostatic approach to “actively charge” dust particles and then impart strong Coulombic force to repulse them from the surface.

The team determined dust particle charge by conducting Stokes experiments under an electrostatic field. “By considering electrostatic, van der Waals, and gravitational forces, we were able to define the threshold electric potential for particle removal,” said Varanasi.

More for You: 8 Hot Applications for Solar Power

Dust particles resting on the bottom electrode in a parallel plate setup were repelled from the surface on application of sufficient voltage. This occurs because of induction that charges the dust. When the same experiment was done with conductive iron particles or insulating Teflon particles, the team observed that dust particles qualitatively behaved more like iron, rather than Teflon.

To activate the system, a simple electrode such as a simple metal bar is passed just over the solar panel's surface, imparting an electrical charge to the dust particles. The team calculated an opposite voltage to apply that was strong enough to overcome the pull of gravity and adhesion forces. When this charge was applied to a transparent conductive layer just a few nanometers thick deposited on the glass covering of the solar panel, the particles were easily repelled.

The team also demonstrated the dust removal system worked well over a broad range of relative humidity, making it effective across a wide range of environments.

"As long as the ambient humidity is greater than 30 percent, you can remove almost all of the particles from the surface, but as humidity decreases, it becomes more difficult,” said Varanasi. The researchers then developed a lab-scale prototype that successfully demonstrated up to 95% recovery of lost power caused by the dust layer.

Editor's Pick: Leveraging Plastic Components for Solar-Powered Applications

Varanasi has proven that a simple electrostatic induction-based system is highly effective for removing the dust that accumulates on solar panels and recovering the energy that would have otherwise been blocked by the dust layer. The team is currently at work at streamlining the next model for testing and scale-up. For example, one possibility is a small electric motor, perhaps driven by electricity derived from a small portion the output from the panel itself, would drive a belt system to move the electrode from one end of the panel to the other, causing the dust to fall away.

Varanasi indicates there has been considerable interest in his technology from various companies including solar installations, utilities, and the private sector.

“We will be scaling up and piloting in real farms as we begin to commercialize the technology, which will likely also include robotic systems that can be used to implement the system on solar farms,” he said.

Mark Crawford is a science and technology writer in Corrales, N.M.