3D Printing Scaffolds for Bone

3D Printing Scaffolds for Bone

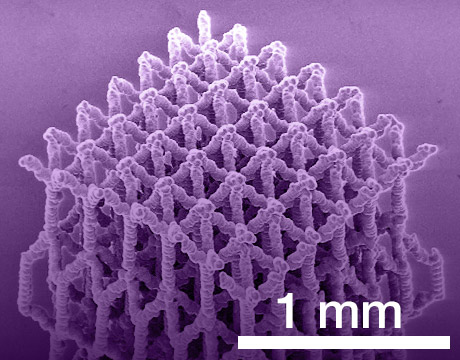

With a new 3D printing method, engineers can print strong, porous materials at the nanoscale. Image: Washington State University

Natural materials like wood and bone, although porous, support great weights and can perform as the scaffolding for tree limbs, buildings, or bodies for a long time without breaking down.

Those materials have what’s termed a high strength-to-weight ratio because their inherent internal structure and their porous nature give them a high surface-to-volume ratio.

But that very architecture makes it hard to mimic these materials through engineered means. Manmade materials with these ultrastrong properties could be used in a range of emerging applications, such as high-performing lithium ion batteries and biological scaffolds.

Now engineers at Washington State University in Pullman, WA, have created a 3D printing method to print structures that can precisely imitate the internal architecture of nature-made materials.

“Most natural materials like wood and bone are lightweight, yet very strong because they have precise control of their structural architectural,” says Rahul Panat, associate professor of mechanical and materials engineering at the university, who led the research. “Arranging nanoparticles in 3D space allows us to mimic these materials.”

Engineers use the technique to print 3D lattices with hierarchical structures, meaning that the structural elements—the rods that connect the lattice--can themselves be made of lattices of even smaller rods. This same hierarchy of structure gives bones their compressive strength.

The first step in the printing process is to create the printing material. For this, researchers crushed a build material into nanoparticles. They used silver to demonstrate the technique, but other materials such as ceramics or different types of metals, anything that can be crushed into nanoparticles, will work, Panat says.

They then mixed the particles with a solvent to create their “ink,” which they then aerosolized. This creates a mist of fog-like microdroplets that contain nanoparticles of silver. An aerosol jet printer next deposits those droplets in precise locations, allowing the researchers to control the size of the pores in the material down to the nanometer, Panat says.

The material is next heated to around 200 degrees Celsius to fuse the nanoparticles and evaporate the solvent. As the liquid in the fog evaporates, the nanoparticles remain, creating delicate metal structures with features as small as 20 microns, the size of a human hair.

Controlling the heating conditions allows the researchers to control the size of pores in the material down to the nanometer, Panat says.

The tiny structures that result look similar to “Tinker Toy” constructions.

The researchers have already created several intricate and beautiful structures, including microscaffolds that contain solid trusses but are created without supporting materials. They’ve also printed stretchable interconnects, spirals, and pillar bridges, electronic connections that resemble accordion bellows, and doughnut-shaped pillars.

By arranging nanoparticles in 3D space, we can maintain the nanoscale benefits of particles while building the total volume. Nature does it in a more random way but the principle is quite similar.

Prof. Rahul Panat, Washington State University

“By arranging nanoparticles in 3D space, we can maintain the nanoscale benefits of particles while building the total volume,” Panat says. “Nature does it in a more random way but the principle is quite similar.”

Indeed the principle is similar because, in creating the printing method, Panat was inspired by the desert rose, a rose-like formation of gypsum or barite, and sand. “I knew of structures in west African deserts that are made from sulfates dissolved in fog droplets,” he says. “The fog condenses and evaporates and leaves the 3D structure that is a desert rose.”’

The team has been at work on the method for two years and now looks forward to exploring several applications to put it to use. For instance, they are developing finely detailed, porous anodes and cathodes for batteries that could replace the solid structures now used. This could significantly increase battery speed and capacity, Panat says.

The 3D printing method could be used to quickly fabricate materials at large scales and could also be used for tissue engineering, microfluidics, and micro-optoelectronics, he says. Biological implants and artificial bones printed using the technique would be lighter and stronger than materials used today.

The researchers are now working to scale the technique so it can be used for large-scale manufacturing. The technology currently uses four print heads that work in tandem to print the materials in three dimensions. But more print heads, potentially hundreds, as is the case of 2D printing applications, will certainly speed the printing process, Panat says.

“This will fill quite a few gaps in existing applications and create entirely new applications,” he says of the printing method.

Jean Thilmany is an independent writer.