Silk Delivers at the Small Scale

Silk Delivers at the Small Scale

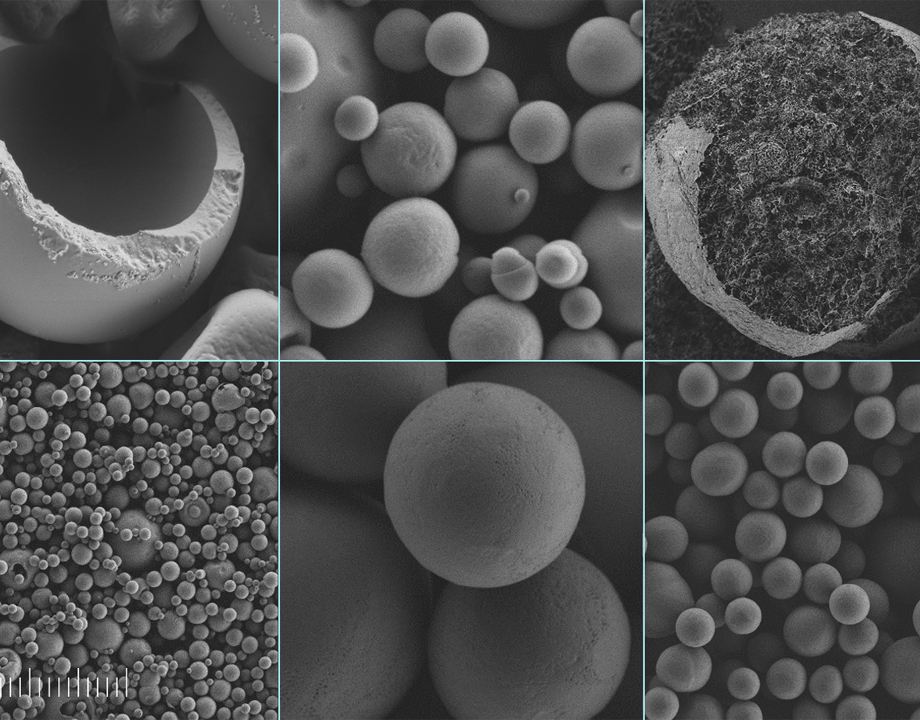

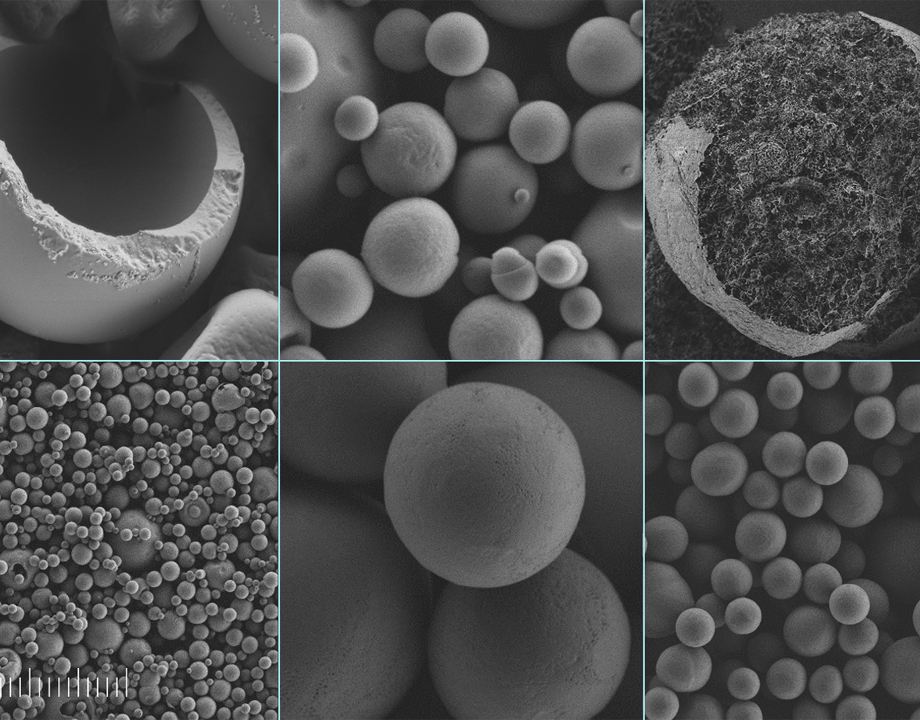

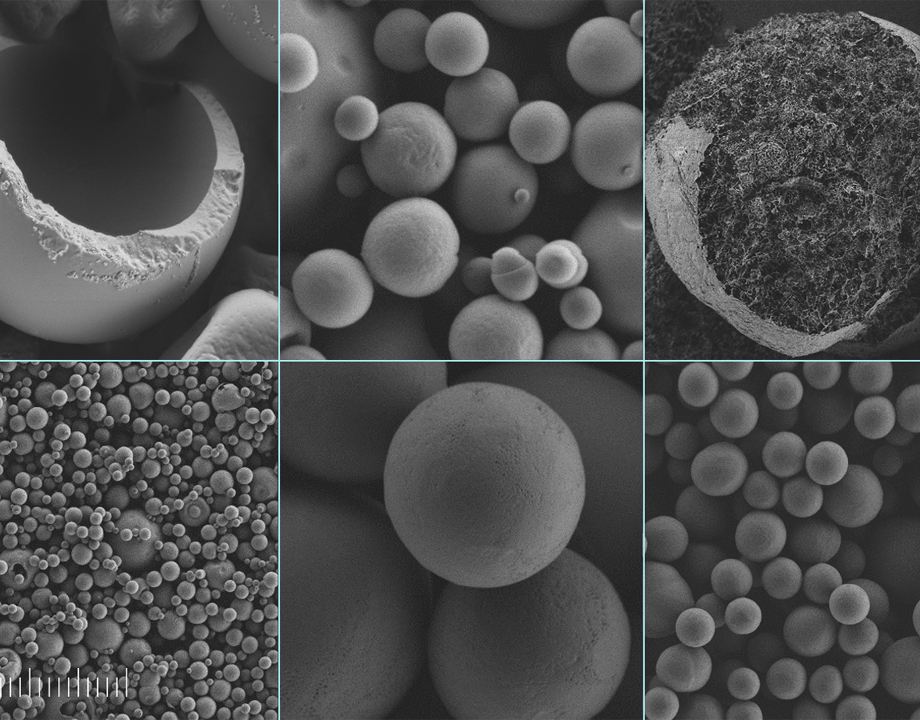

Plastic microbeads make great delivery devices but are winding up in the bloodstreams of fauna planetwide. Worms to the rescue. SEM images by Muchun Liu, edited by MIT News.

The world’s plastic problem isn’t restricted to the macro-sized trash floating about our oceans and stocking our landfills. Plastic microbeads, used in paints, agriculture, and cosmetics, are just as serious an environmental threat and are increasingly found in animals all over the world. In an effort to combat the problem, the US has banned the use of microbeads in cosmetics and the European Union has moved to outlaw them completely by 2025.

But the purpose of microbeads—the delayed delivery of what they hold inside—makes them near essential to the industries listed above. Herbicides have to be released slowly over time, so they don’t kill the plants they are trying to protect. Cosmetics release vitamins when applied to their target area. With plastic, pores in the beads and mechanical breakdown control the timing of payload delivery. But the plastic itself, of course, doesn’t break down.

You Might Also Like: Using Muscle to Spin Fiber

Now researchers at MIT have created a substitute microbead made of a material that is far more biodegradable than plastic: silk.

“We are using silk because it has a natural polymorphism,” said Muchun Liu, a postdoctoral associate at the university and lead author of the paper "Microencapsulation of High-Content Actives Using Biodegradable Silk Materials," which appeared in the journal Small in July. “When the silk is in the silkworm, it’s in liquid form. When it spins out, it automatically transforms into this crystallized insoluble form.”

That form can be returned to its malleable state through a simple and sustainable process. Liu and her team proved it by first cutting and boiling silk cocoons in water and sodium carbonate to remove their keratin layer, then they used lithium bromide to dissolve the silk.

“It’s all physical,” said Liu, “We’re not chemically modifying they polymer, just breaking the hydrogen bonds.” Later, when it’s time to reshape the silk, the hydrogen bonds are re-introduced.

More Like This: Fixing Bones With Spider Milk Composite

The resultant product is not just good for the planet, it’s also good for our bodies. “You can eat silk,” said Benedetto Marelli, a professor of civil and environmental engineering at the university and co-author of the study. And it’s not just the process that’s sustainable. Each silk cocoon produces a single thread of silk, so if there’s any deformation, or if the thread is not long enough, silk producers discard it. “But we’re not interested in the fiber,” said Marelli. “So, we can tap into the waste of the silk industry.”

Should their technique catch on so much that they end up using more silk than the silk industry currently creates as waste, producing more silk might still prove sustainable. “As long as the agriculture around planting mulberry trees is done in a sustainable way, then using more silk means having more trees in the environment,” noted Marelli.

The bond-broken silk is nearly as versatile as the plastic it’s meant to replace. The polymer chains can be organized so that the material can be tuned to work with existing encapsulation machinery. It can also be made as hydrophilic or hydrophobic as an application calls for.

“Different folding provides different properties,” said Marelli. “Think about this protein as a very long noodle. When you release a noodle on a table it’s going to be randomly distributed. If you carefully position the noodle, it can get a more ordered structure.”

Continue Your Read: Intercepting Water Plastic Pollution

Marelli and Liu tested their silk beads with an herbicide. It performed as well as, if not better, than the plastic beads have been doing the job on farms.

“The hope is that other researchers will jump into this work,” said Marelli. “The whole society has benefited so much from plastic, but in the last century the focus was the health of people—now we need to start focusing on the health of the planet. This is where everyone needs to come together—consumers, policy makers, academia—to find a way to replace some of these plastic components with biodegradable ones.”

Michael Abrams is a technology writer based in Westfield, NJ.