Using Plasma to Reduce Tunnelling Times and Cost

Using Plasma to Reduce Tunnelling Times and Cost

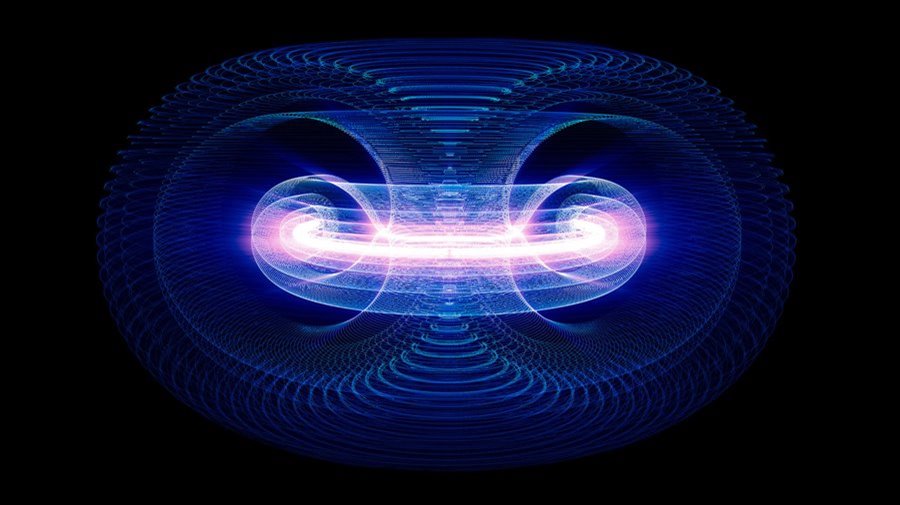

Plasma torches burn hot enough to burst through rock for tunnels.

There are typically two methods used to build tunnels, depending on their size and geology. Tunnel boring machines use a rotating cutterhead at the tip of the machine that pushes it through soft ground or rock. For very hard rock, tunnellers use rigs to drill holes where explosives are placed and then set off; the resulting rubble is then collected and carted out of the tunnel for disposal.

Both methods work, but underground infrastructure is expensive to build. Now, a new method using plasma arc torches may speed the rate of tunnelling and bring costs down. California startup EarthGrid is working with plasma torches mounted on a tracked robot to blast rock into small pieces at a greater speed. Company officials believe dramatically reduced tunnelling costs will make projects once considered too expensive to be cost-effective.

In a series of tests that led to the development of the patented technology, Earthgrid engineers used plasma torches to break and even vaporize hard rock. Working at temperatures that reach 7,000 ˚F , the plasma creates a chemical reaction to help break down rock faster. The company claims it will be able to tunnel up to one kilometer per day, or a whopping 100 times faster than standard technology.

“It depends on the geology, but the testing we’ve done at those temperatures, we’ve been able to demonstrate speeds ranging..from about 400 meters to 1,200 metes per day,” said Troy Helming, Earthgrid CEO.

Unlike traditional TBMs that carve out circular tunnels, Earthgrid’s machine is designed to produce an arch. The firm now is building a full-size rig that will be able to blast a 2.5-meter tunnel in the shape of a horseshoe arch. After consulting with various tunneling contrators, Helming said lining will done using conventional shotcrete spraying using a rig directly behind the excavator.

Mucking will be done using a vacuum cart to suck material away from the rig through inlets at the bottom of the shield. Excavated material will be small bits of gravel, sand, and silt, loaded into the removal equipment that sends it back for disposal.

Become a Member: How to Join ASME

Helming, an entrepreneur who previously founded solar- and wind-energy projects, started Earthgrid after being stymied in developing a solar farm in California. It’s capacity had to be reduced by 75 percent because it was too expensive to transmit the power from its remote location.

“Had we been able to get underneath three miles of protected wetlands and creeks in California, we could have gotten to a beefier part of the grid and we wouldn’t have had to downsize by 75 percent,” he said.

While commiserating with the team, Helming said one the engineers started telling stories about cutting through a ship’s hull with plasma torches while a Navy SEAL. That sparked the idea, and set Helming to research using plasma to blast rock.

“No one was doing this, although some plasma rock work was done at Los Alamos National Laboratory in the 1970s,” he said. “Turns out you can bore at this speed.”

Helming believes he can tunnel at a cost of about $300 per meter, depending on the geology and the cost of electricity.

The rig will operate electronically without any fossil fuels. Depending on the source of the electricity, tunnelling would be emissions-free. “Our primary operating expense is electricity,” he said.

More for You: Building Dexterity into Robotic Hands

Helming said the hardest rock they’ve successfully tested the technology on is basalt/quartz mixture that was 360 mPa, moving at an extrapolated speed of almost 500 meters per day.

The rig now being built is called the Rapid Burrowing Robot, with several 48,600 ˚F plasma torches mounted on discs. They are arranged in a Fibonacci spiral, to widen out away from center for full coverage.

Patents for the technology show power estimates of about 40 MW for a version of the rig using 72 plasma torches to drill a 1-meter bore. High-power settings could draw 120 MW. Using high-speed configuration, the company estimates it can tunnel up 1 kilometer per day. For comparison, Elon Musk’s Boring Company moves at about 0.24 kilometers per day with its Prufrock TBM, with a goal of eventually advancing 1.13 kilometers per day.

Earthgrid officials noted lower operating costs with the plasma machine come from not having to change drill bits or cutter heads, lower energy consumption, fewer workers, easier spoils removal, and elimination of drilling mud or chemicals.

The firm also is developing a trenching robot using plasma torches that can be used for working in rock. The trencher would not operate as efficiently due to greater heat loss. Helming said Earthgrid is targeting the utility market with both machines, as well as emerging markets such as delivery services.

Pipedream Labs, for instance, uses an underground delivery system to move goods quickly through pipes or tunnels. Helming said Earthgrid has contracts signed with Pipedream and others to build tunnels that would be used to move goods quickly to delivery points using robots.

Earthgrid is not the only firm pursuing plasma tunnelling. San Francisoc-based Petra is developing similar technology. When fully developed, it may drill its own niche into underground construction.

John Kosowatz is senior editor.

Both methods work, but underground infrastructure is expensive to build. Now, a new method using plasma arc torches may speed the rate of tunnelling and bring costs down. California startup EarthGrid is working with plasma torches mounted on a tracked robot to blast rock into small pieces at a greater speed. Company officials believe dramatically reduced tunnelling costs will make projects once considered too expensive to be cost-effective.

In a series of tests that led to the development of the patented technology, Earthgrid engineers used plasma torches to break and even vaporize hard rock. Working at temperatures that reach 7,000 ˚F , the plasma creates a chemical reaction to help break down rock faster. The company claims it will be able to tunnel up to one kilometer per day, or a whopping 100 times faster than standard technology.

“It depends on the geology, but the testing we’ve done at those temperatures, we’ve been able to demonstrate speeds ranging..from about 400 meters to 1,200 metes per day,” said Troy Helming, Earthgrid CEO.

Unlike traditional TBMs that carve out circular tunnels, Earthgrid’s machine is designed to produce an arch. The firm now is building a full-size rig that will be able to blast a 2.5-meter tunnel in the shape of a horseshoe arch. After consulting with various tunneling contrators, Helming said lining will done using conventional shotcrete spraying using a rig directly behind the excavator.

Mucking will be done using a vacuum cart to suck material away from the rig through inlets at the bottom of the shield. Excavated material will be small bits of gravel, sand, and silt, loaded into the removal equipment that sends it back for disposal.

Become a Member: How to Join ASME

Helming, an entrepreneur who previously founded solar- and wind-energy projects, started Earthgrid after being stymied in developing a solar farm in California. It’s capacity had to be reduced by 75 percent because it was too expensive to transmit the power from its remote location.

“Had we been able to get underneath three miles of protected wetlands and creeks in California, we could have gotten to a beefier part of the grid and we wouldn’t have had to downsize by 75 percent,” he said.

While commiserating with the team, Helming said one the engineers started telling stories about cutting through a ship’s hull with plasma torches while a Navy SEAL. That sparked the idea, and set Helming to research using plasma to blast rock.

“No one was doing this, although some plasma rock work was done at Los Alamos National Laboratory in the 1970s,” he said. “Turns out you can bore at this speed.”

Helming believes he can tunnel at a cost of about $300 per meter, depending on the geology and the cost of electricity.

The rig will operate electronically without any fossil fuels. Depending on the source of the electricity, tunnelling would be emissions-free. “Our primary operating expense is electricity,” he said.

More for You: Building Dexterity into Robotic Hands

Helming said the hardest rock they’ve successfully tested the technology on is basalt/quartz mixture that was 360 mPa, moving at an extrapolated speed of almost 500 meters per day.

The rig now being built is called the Rapid Burrowing Robot, with several 48,600 ˚F plasma torches mounted on discs. They are arranged in a Fibonacci spiral, to widen out away from center for full coverage.

Patents for the technology show power estimates of about 40 MW for a version of the rig using 72 plasma torches to drill a 1-meter bore. High-power settings could draw 120 MW. Using high-speed configuration, the company estimates it can tunnel up 1 kilometer per day. For comparison, Elon Musk’s Boring Company moves at about 0.24 kilometers per day with its Prufrock TBM, with a goal of eventually advancing 1.13 kilometers per day.

Earthgrid officials noted lower operating costs with the plasma machine come from not having to change drill bits or cutter heads, lower energy consumption, fewer workers, easier spoils removal, and elimination of drilling mud or chemicals.

The firm also is developing a trenching robot using plasma torches that can be used for working in rock. The trencher would not operate as efficiently due to greater heat loss. Helming said Earthgrid is targeting the utility market with both machines, as well as emerging markets such as delivery services.

Pipedream Labs, for instance, uses an underground delivery system to move goods quickly through pipes or tunnels. Helming said Earthgrid has contracts signed with Pipedream and others to build tunnels that would be used to move goods quickly to delivery points using robots.

Earthgrid is not the only firm pursuing plasma tunnelling. San Francisoc-based Petra is developing similar technology. When fully developed, it may drill its own niche into underground construction.

John Kosowatz is senior editor.

Pulse of the Profession: CAD in 2030

CAD technologies and their applications are rising in tandem with trends in Industry 4.0.