4D Printing Advances Additive Manufacturing

4D Printing Advances Additive Manufacturing

“4D” printing is an emerging technology that 3D-prints solid components programmed to change into other shapes when certain environmental parameters - temperature, light, and humidity – are reached. Thus, the “fourth dimension” is, literally, transformation. This ability depends on the development and use of unique programmable materials. Although 4D printing is still an emerging field, it has huge potential for expanding engineering design.

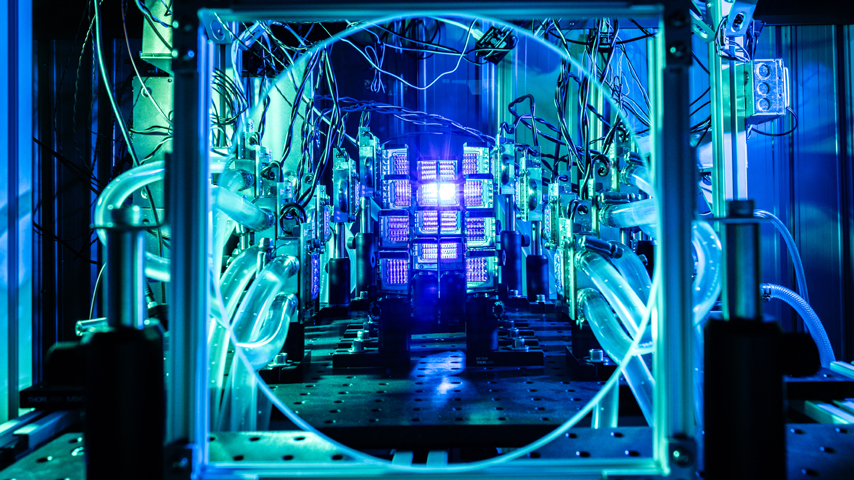

Currently 4D printing requires complex and time-consuming post-processing steps to mechanically program each component. Also, most commercial printers can only print 4D using a single material, which greatly limits design choices. But a research team led by Jerry Qi, a mechanical engineering professor at Georgia Institute of Technology, along with scientists at the Singapore University of Technology and Design, have developed a powerful new 4D printer that can create self-assembling 4D-structures much more quickly and efficiently.

For You: The latest in manufacturing and design breakthroughs

“We call it the multi-material multi-method [m4] 3D printer,” Qi says. “It is a very powerful 3D printing system that integrates four printing methods into one single platform, which enables the efficient printing of complicated parts that can change shape, thus expanding future printing applications.”

The researchers envision it being used for a variety of applications in such industries as aerospace and medicine. Their paper about the technology was recently published in ScienceDaily.

The m4 3D printer is a very powerful 3D printing system that integrates four printing methods into one single platform.Prof. Jerry Qi, Georgia Institute of Technology

How It Works

Qi’s printer combines four different printing technologies: aerosol, inkjet, direct ink write, and fused deposition modeling. It can make products from a variety of materials including hydrogels, conductive inks, elastomers, and shape memory polymers, which can be programmed to "remember" a shape and then transform into it when heated to a certain temperature.

Using his printer and a special composite material made from acrylic and epoxy, Qi successfully 4D-printed objects that transformed shape up to 90 percent faster than previously possible because the tedious mechanical programming steps were already integrated into the 3D printing process. Composites can offer significantly improved physical properties and greater functionality, compared to single materials.

“When two or more materials that respond differently to environmental stimuli are combined together into a composite material, there will be some incompatibility in the structure,” Qi says. “We can thus harness this incompatibility and design structures that can dramatically change in shape.”

For multiple polymers, their property-structure-processing relationships can be very complicated and very material-specific. For example, Qi combined an elastomer and a glassy polymer to create a one-way 4D printing transformation, where the shape is permanent and cannot change upon later cooling or heating. In another case, Qi combined an elastomer and a liquid crystal elastomer to create a product with a reversible shape capability, where the shape can change back and forth with changes in temperature.

A key engineering challenge in designing the system was the integration of the control modules for the different printing methods. The printer is controlled by an in-houseDeveloped software platform using Python code.

“So, you can hit one button and then the printing job starts, without human intervention in the middle of the printing process for multiple material and multiple methods printing,” Qi says. “This requires very careful design of software, including passing control commands to different printing modules, transforming coordinate systems when different printing methods are used, and coordinating printing layer thickness.”

The system also requires a very large, 6,000-pound granite table. “This is because we need to shuttle the printing platform to different printing modules and the zDirection variations must be within three microns,” Qi says. “Any steel board will warp more than 3 microns when the temperature changes slightly. Thus, only a large piece of granite provides the stability to maintain such accuracy.”

Future Possibilities Abound

When most people see the m4 printer for the first time, the “aha” moment is when they realize the level of integration it takes to combine four different printing capabilities into one single printing platform. Qi is collaborating with several companies to see how the m4 printer might be helpful in solving some of their unique product design challenges. He is also working with Children's Healthcare of Atlanta to determine whether this new technology can print prosthetic devices for children.

"We are on the cusp of creating a new generation of devices that could vastly expand the practical applications for 3D and 4D printing," says Qi. "Our prototype printer integrates many features that appear to simplify and expedite the processes used in traditional 3D printing. As a result, we can use a variety of materials to create hard and soft components at the same time, even incorporating conductive wiring directly into shape-changing structures, and ultimately set the stage for the development of a host of 4D products that could reshape our world."

Mark Crawford is an independent writer.

Read More:

How to Pump Extremely Hot Metal

A Robotic Gym … For Babies

Robots Modeled on Bees Sense Rather than Think