Meet Your Robotic Coworkers

Meet Your Robotic Coworkers

In the age of advanced automation, new robots with machine learning and autonomous capabilities are your future coworkers.

Most robots still work on assembly lines, but a small and growing number of mobile robots have begun to edge their way into industry. One dynamic proving ground for these smarter and more capable mobile automatons is inspection and maintenance.

Engineers are already using inspection robots to identify hot spots on refinery exhausts, check boilers for metal loss and corrosion, and examine machinery without disassembling it.

Yet, despite their sophisticated sensors and machine learning algorithms, few can do anything about a problem once they spot it. It still takes a human technician to maintain or repair a structure.

This is beginning to change. A handful of inspection robots have begun to evolve into robots that can do maintenance tasks and even make the occasional repair on the spot.

As they evolve, these devices will change the relationship between robots and workers. While pure inspection robots may replace labor—they do not require anyone to build scaffolds or perform monotonous tests—many still require workers to pilot them and interpret the images and data they report.

Maintenance robots are trickier. Robots excel at inspection because it is a repetitive task that requires precision. A robot can run the same check on the same point of a pipeline or bridge in exactly the same way every time.

Even routine maintenance is rarely that straightforward. It involves lots of variation and often some surprises. To be effective, maintenance robots need to work closely with humans.

That’s a good thing, argues Tim Westhoven, scouting and ventures advisor for ExxonMobil. A robot’s ability to make precise, repetitive measurements—and ultimately repairs—cuts down on human variability.

In fact, he argues that human variability and error cause 40 to 70 percent of all reliability issues in factories. Those errors could result in anything from product rework and line stoppages to fires and explosions. Curbing human variability is one of the main reasons companies turn to robots for inspection and maintenance.

“Freeing technicians from the more mundane and most difficult tasks allows them to do what they do best—planning, adapting to changing conditions, and using expert judgment to guide a repair operation,” he said.

That is a lofty goal for maintenance robots. So, how close do they come to achieving it?

Service Robots

Assembly line robots have been on a roll for the past five years. The world’s robot population doubled, and vendors shipped nearly 400,000 units in 2018, according to the International Federation of Robotics. Once limited primarily to automotive production, they are now found in a wide range of factories. In South Korea and Germany—by far the most robot-heavy nations—there is now one robot per 14 to 15 workers.

The service robot sector is growing even faster. The largest uses are in warehouses (to move products), medicine (especially surgery), agriculture (milking is big), and defense (drones and anti-bomb devices). They often have some degree of autonomy and are often designed to work with people.

Inspection and maintenance robots are considered service robots, and their numbers are growing rapidly. In Japan, they made up 8.6 percent of the service robot market in 2017. Dozens of companies and startups are developing hardware and data solutions for more open-ended inspection and maintenance tasks.

Most of these robots were built to do one specific task well, said Bob Doyle, vice president of the Robotic Industries Association.

Read more about Rescue Robots

“Startup companies or new technology research programs are finding the most success when they design robots for specific work cases,” Doyle said. “The concept of a robot doing everything for everyone is still pretty far out there. Starting with a specific use case helps with adoption.”

GE’s lineup of visual inspection robots is an example. These specialized robots are designed to crawl along the bottom of storage tanks to check for corrosion or through pipes to search for wall thinning that indicates corrosion.

The company also developed solutions that combine specialized inspection and maintenance. Its Boiler Wall Cleaning & Inspection (BWCI) Robot, for example, is designed to inspect—and clean—boiler waterwalls, the welded array of tubes that carry water through the boiler for heating.

Ordinarily, this would be done by dismantling the boiler and building a scaffold for a human inspector to inspect and clean them. BWCI, on the other hand, uses four magnetic rollers to climb across the tubes.

The operator stays outside the boiler, using advanced cameras and sensors to inspect the tubes and blast away fouling with high-pressure water jets.

GE optimized its Fast Cleaning Robot for a different task. Its low profile and mechanical tracks let it get under hard-to-reach structures. Once there, it cleans, polishes, grinds, and paints.

While these robots help workers get to difficult-to-reach work areas, they have limits. They take time and labor to deploy. They require human pilots and a significant amount of power and data cabling.

Editor’s Pick: A Robot for the Every Factory

Despite the drawbacks, they are faster than human inspection and maintenance. That is one of their big selling points, said John Lizzi, executive director for robotics at GE Research.

“Taking a customer asset out of operation for maintenance, while critical, prevents it from delivering value to the end customer,” he said. “We want to reduce such downtime as much as possible and robotics is increasingly a key technology we use to do that.”

Small is Better

Another way to speed maintenance is to deploy small robots that can enter machinery without dismantling it first.

“Think of it as minimally invasive surgery for machines and other types of confined spaces,” said Lizzi, who has jet engines and wind turbines in mind.

“The inner workings of turbo-machinery such as gas turbines and aircraft engines are complex,” he said. “Today a borescope is typically used for inspection but their reach can be limited. Miniature robotic systems can be used to provide new levels of access, degrees of freedom, and new inspection and repair methods inside such small and complex areas.”

GE’s small inspection robots vary in size and scope, and some perform limited maintenance as well. Some use caterpillar tracks to crawl inside an engine. Others have magnetic rollers to climb turbine walls and operate upside down.

GE has several maintenance procedures under development, available only to certain GE customers. They include using robot-mounted grinding tools to smooth abrasions and small robotic arms to apply ceramic coatings to damaged surfaces. Both involve making repairs without disassembly.

"Greater autonomy and the ability to apply precise force at small scales will make the robots even more useful," Lizzi said.

GE sees robotic systems such as these moving through three phases: robots as tools, robots as teammates, and self-sustaining systems.

The second level sees robots as partners that translate general commands into action. Tell this type of robot to go somewhere and it will make real-time adjustments based upon potential obstacles and collisions.

GE wants a robot that could perform a complex sequence of repair procedures automatically based on simple human instructions.

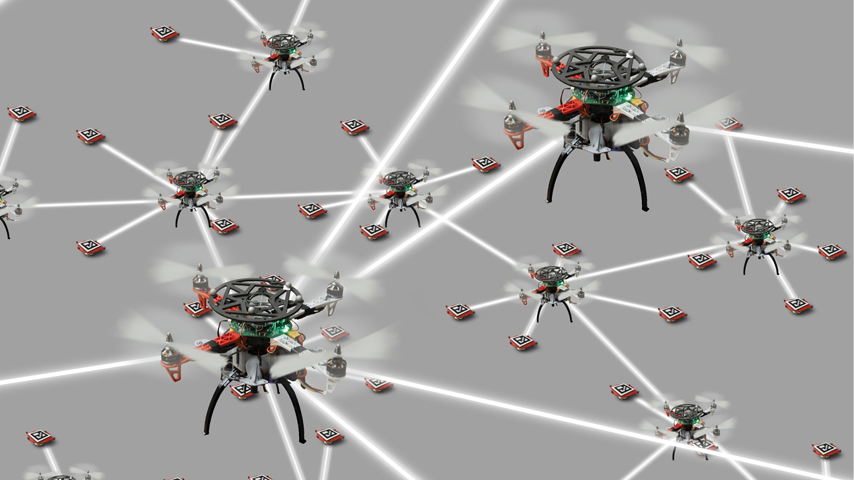

GE is not the only company thinking small. Rolls-Royce, another turbine maker, wants to create teams of tiny SWARM robots to do visual inspections of jet engine interiors without taking them apart. This could reduce inspection times to minutes, from five hours now.

Rolls-Royce developed SWARM bots jointly with University of Nottingham and Harvard University’s Wyss Institute, which emphasizes biologically inspired design and may explain why they look like four-legged bugs.

The SWARM bots are 4.5 cm long, 1 cm in diameter, and weigh only 1.5 grams. A robotic snake delivers them into the interior of the aircraft, where they train their cameras on various parts.

“They have eight degrees of freedom and with four legs can move horizontally and vertically,” said Sebastien de Rivas, a Wyss Institute research fellow. “Because of this, we have been able to achieve tasks that similar sized robots have been unable to do up until now.”

One of those tasks is crawling upside down inside an engine.

“In 1.5 grams of robot here, we have about eight years of research, making it a concentrated technology that can’t be found anywhere else on earth,” Rivas said.

Under the Sea

Offshore oil platforms, subsea infrastructure, and ships are also interested in inspection and maintenance robots, since their assets are isolated, costly and time-consuming to reach, and often dangerous for humans.

This gives rise to some innovative engineering. One example is Norway’s Eelume, a self-propelled underwater robotic arm commercialized by a startup (Eelume) spun off from the Norwegian University of Science and Technology.

The snake-like Eelume mounts thrusters, sensors, and payload along any section of its segmented body. By bending into a U-shape, it can apply different tools on each of its ends to a single task. It is strong enough to hover in strong ocean currents for precise maintenance procedures. It operates down to 500 meters, deep enough to serve most oil and gas platforms and subsea systems in the North Sea and Gulf of Mexico.

“The original concept was to develop a walking fire hose that could enter buildings remotely and put out fires,” said Dave Mackay, who doubles as sales manager at Eelume and its commercial and technology partner, Kongsberg Maritime.

Mackay sees Eelume delivering big economies: “Currently, when offshore oil and gas companies want to carry out an inspection, maintenance, and repair activity, they will have to contract a surface vessel with divers or remotely operated underwater vehicles aboard. These vessels can cost anywhere from $80,000 to $350,000 daily and take significant amount of time to deploy.”

Eelume, on the other hand, lives permanently in a seabed docking station and can carry out inspections and light maintenance and repairs 24/7. This generates major cost savings over the lifetime of an oil platform.

Eelume inspects underwater objects autonomously, once a human has walked its machine learning system through the routine several times. These inspections are done wirelessly.

Maintenance and repair tasks require a human operator. He or she directs the robot to mount end effectors—grabber, torque tool, cathodic protection probe, cleaning tool, or sonar—stored in the underwater docking station. With these tools, the operator can remove debris, clean metal structures, test for corrosion, and even turn subsea valves on and off.

Eelume has partnered with Norwegian oil and gas giant Equinor to test the robot. The firm is currently putting Eelume through a series of underwater proof trials.

“Once those have been successfully completed, we expect to be installing the first two subsea resident Eelume systems on one of Equinor’s giant subsea production oil fields later this summer,” Mackay said.

Humanoids

Swimming, crawling, and rolling robots are all examples of robots developed for specific maintenance operations. They are, in the end, tools.

To create a robot that is flexible enough to partner with humans is a greater stretch. Not only must it understand what we are doing, but it must be able to do human things—react to spoken commands, navigate new environments, and pitch in to help at the right time.

“People have been talking about developing a humanoid robot for a long time,” said the Robotic Industries Association’s Doyle. “And no one’s really been able to do one yet.”

That is not stopping SecondHands, a European research consortium. Its ARMAR-6 prototype is a rolling, human-sized, two-armed robot that works alongside human technicians. Its AI recognizes specific tasks and its arms can grip human tools.

“The opportunity of using a humanoid robot is to assist the maintenance technician,” said Duncan Russell, research development manager for Ocado Technology, a consortium member now testing ARMAR-6 in its highly automated warehouses.

Rather than performing a single type of maintenance task, the robot operates like a true maintenance assistant.

“It can hold the right type of equipment, react properly while recognizing the action the technician is performing, understanding the process, and provide the right level of help at the right time,” he said.

The five-year research project is now in its fourth year. A current use case involves cleaning overhead structures.

“The robot will observe the technician starting that task and move into position to help hold the guard plate and lower it,” Russell said. “It can use the sensors in its arms to work with the human and comfortably follow him.”

The robot already knows this task. As the human works, ARMAR-6 identifies and hands over the necessary tools (in this case, spray cleaner and cloth) and replacement parts.

The robot draws on a variety of research. Karlsruhe Institute of Technology provided the mechanical design and operating system, including grasping and speech processing capabilities. University College of London designed the vision system used to identify objects and the human’s work pose. The Swiss Federal Institute of Technology Lausanne (EPFL) and the Sapienza University of Rome provided the action learning capabilities and the artificial intelligence system, respectively. The project is funded by the EU fund Horizon 2020 (project grant agreement #: H2020-ICT-2014-1).

“The robot itself has had to be adaptable to different situations,” Russell said. “We ended up with a humanoid robot, because that makes it a lot more friendly for people to work alongside and because it can handle working in a human world alongside humans.”

Are We Ready for Robots?

Despite positive economics, any automation process raises workplace acceptance issues. After all, workers afraid of losing jobs to robots are not going to willingly embrace them.

In today’s hot economy, that is less of an issue. As RIA’s Doyle notes, most companies are worried about recruiting qualified employees, not firing workers.

“When people tell me that robots are going to take all the jobs, I immediately say, ‘I want more robots,’” he said. “It’s not something we should fear, rather something we should embrace. It’s not a replacement but rather a tool.”

Human operators who worked with ARMAR-6 responded with positive reviews, even if they were apprehensive at first.

“There was a significant improvement in their attitude toward working with a robot after the experience of working with it on the floor,” Russell said. “Although the performance wasn’t as fast as they would have liked or expected, the actual interaction with the robot was quite positive.

“They certainly welcomed the help in their tasks, because it was providing the right level of help,” he added.

"Our workforce generally wants these kinds of changes,” ExxonMobil’s Westhoven said. “They recognize that rapidly adopting these technologies to our operating facilities will produce enormous benefits. Every time you can eliminate risk to a human worker and improve upon maintenance time, you create a more efficient process."

And efficiency, in the end, is what keeps jobs safe in a competitive global economy. ME

Carlos M. Gonzalez is special projects manager

Register for ASME’s Robotics for Inspection and Maintenance Forum