Ready-to-Go Multi-Material 3D-Printed Parts

Ready-to-Go Multi-Material 3D-Printed Parts

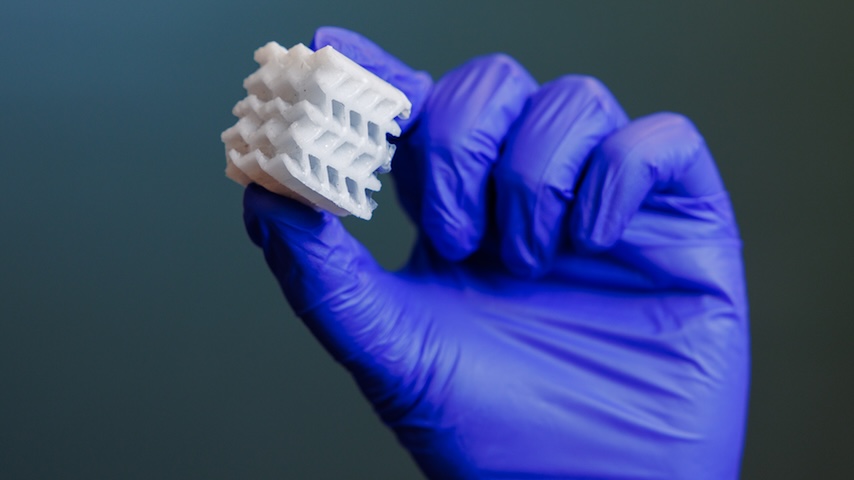

Researchers at Columbia Engineering have invented a new additive manufacturing technique that allows multiple materials to be used in a single print.

While selective laser sintering (SLS), which uses a laser to melt and fuse metal or plastic powders into a three-dimensional object, is one of the industry’s most desired methods of additive manufacturing because of its strength and reliability, some limitations have prevented it from reaching full potential.

Now, researchers at Columbia Engineering have invented a new technique that could overcome arguably the biggest limitation, opening the door to fabricating components out of multi-materials that will be fully formed complex systems when they come out of a 3D printer. The researchers, who have robotics backgrounds, can foresee the potential of printing everything from circuit boards to electromechanical components and even fully assembled robots. The new technique involves inverting a laser to melt and fuse micron-scale powdered materials together to form a three-dimensional object.

In traditional SLS printing, the laser points downward onto a heated print bed building a part from the bottom up, layer by layer, until an object is completely formed. Once ready, the part has to be “excavated” from a pile of excess surrounding particles, which in most instances can’t be re-used. Furthermore, with this method, only one material can be used during the print process; it produces a lot of waste, has a negative environmental impact because of all the excess dust, and could trigger a dust explosion, according to Hod Lipson, professor, and researcher in robotics, artificial intelligence, digital design and manufacturing at Columbia Engineering and director of the Creative Machines Lab.

Take Our Quiz: How Well Do You Know the 3D Printing Industry?

Working as a team, Lipson and his Ph.D. student John Whitehead, set out to eliminate the powder bed altogether. They did so by coating glass plates, each with a thin layer of one of two different powders, thermoplastic polyurethane (TPU) and a polymer, Nylon 12, and lowered a print platform onto the upper surface of one of the plates. Then they directed a laser beam up from below the plate. The laser selectively sinters some of the powder onto the print platform based on a pre-programmed virtual blueprint. The platform is then raised with the fused material and moved to another plate, and placed either on top of or beside the different powder, and the sintering process is repeated until the part is completed.

“We reverse the process, and we build a part upside down,” Lipson said. “The main benefit is we don’t need a lot of powder because you have only a small dusting at a time, and secondly, we can work with multiple powders, which I think is a game-changer for the industry,” Lipson said. “So many things are made out of multiple materials. Real things. I think that’s going to be a missing piece of this whole industry.”

Their work was described in an article in the December issue of Additive Manufacturing.

Learn More About: Advancing Additive Manufacturing in Aerospace

For the demonstration, they chose the two materials, TPU, and nylon, because they contrast well visually (black and white) and also can both be sintered at temperatures using a relatively weak laser (for safety reasons). Two examples of what the team has produced include a yin-yang symbol that is about 19x19x0.7 mm and a butterfly at about 25x32x0.6 mm.

“The integration of these two materials would have been impossible using a standard SLS system,” Whitehead said.

There are a number of fields the team envisions for which the technique offers potential value. For example, Whitehead said, medical implants that “have to be highly customized and conform to some kind of pre-existing geometry or biology and also have to be fairly robust. A lot of that lends itself to metal additive manufacturing,” and the team’s next step will be to prove that the technique works with metal. After that, there are a number of other possibilities, such as embedding electronics in print and burying a microchip inside, which now can only be done afterward.

Noting the benefit in creating knee and hip implants, for example, Lipson said they often require soft material at the core and hard material on the outside to prevent the implant from being stronger than the bone, which could cause the implant to break the bone. “You have to match it, and this is a very tricky thing. Multi-material is the way to do it, and now it’s not possible,” he said.

You May Also Like: 3D-Printed Algae Boosts Regenerative Medicine

Looking ahead, the team is excited about the prospects of combining different approaches to additive manufacturing. “Today you have to choose, do you want to go powder or liquid or do you want to go extruded plastic [FDM or Fused Deposition Modeling],” Lipson said. “You have to choose one, and then you’re stuck with it. Each has pros and cons. With our approach, you can do a little bit of this and a little bit of that, go back and forth and get the benefit of all. You can make something very strong with SLS but also smooth and watertight [with SLA (stereolithography), another form of 3D printing]. You can do all of them at the same time. It’s unexplored territory.

“My experience is that a lot of people are saying 3D printing was all hype. In 2015, it was all the rage. Now nobody’s talking about it. But (based on spending) on the technology and services and products around it, it’s still continuing to grow exponentially. Once this technology can expand from single material parts to multi-material parts, all bets are off. At that point, it’s going to explode in even more things.”

Nancy Giges is a technology writer based in White Plains, NY.

Register Today for the AM Industry Summit: Convergence of Aerospace & Energy

Now, researchers at Columbia Engineering have invented a new technique that could overcome arguably the biggest limitation, opening the door to fabricating components out of multi-materials that will be fully formed complex systems when they come out of a 3D printer. The researchers, who have robotics backgrounds, can foresee the potential of printing everything from circuit boards to electromechanical components and even fully assembled robots. The new technique involves inverting a laser to melt and fuse micron-scale powdered materials together to form a three-dimensional object.

In traditional SLS printing, the laser points downward onto a heated print bed building a part from the bottom up, layer by layer, until an object is completely formed. Once ready, the part has to be “excavated” from a pile of excess surrounding particles, which in most instances can’t be re-used. Furthermore, with this method, only one material can be used during the print process; it produces a lot of waste, has a negative environmental impact because of all the excess dust, and could trigger a dust explosion, according to Hod Lipson, professor, and researcher in robotics, artificial intelligence, digital design and manufacturing at Columbia Engineering and director of the Creative Machines Lab.

Take Our Quiz: How Well Do You Know the 3D Printing Industry?

Working as a team, Lipson and his Ph.D. student John Whitehead, set out to eliminate the powder bed altogether. They did so by coating glass plates, each with a thin layer of one of two different powders, thermoplastic polyurethane (TPU) and a polymer, Nylon 12, and lowered a print platform onto the upper surface of one of the plates. Then they directed a laser beam up from below the plate. The laser selectively sinters some of the powder onto the print platform based on a pre-programmed virtual blueprint. The platform is then raised with the fused material and moved to another plate, and placed either on top of or beside the different powder, and the sintering process is repeated until the part is completed.

“We reverse the process, and we build a part upside down,” Lipson said. “The main benefit is we don’t need a lot of powder because you have only a small dusting at a time, and secondly, we can work with multiple powders, which I think is a game-changer for the industry,” Lipson said. “So many things are made out of multiple materials. Real things. I think that’s going to be a missing piece of this whole industry.”

Their work was described in an article in the December issue of Additive Manufacturing.

Learn More About: Advancing Additive Manufacturing in Aerospace

For the demonstration, they chose the two materials, TPU, and nylon, because they contrast well visually (black and white) and also can both be sintered at temperatures using a relatively weak laser (for safety reasons). Two examples of what the team has produced include a yin-yang symbol that is about 19x19x0.7 mm and a butterfly at about 25x32x0.6 mm.

“The integration of these two materials would have been impossible using a standard SLS system,” Whitehead said.

There are a number of fields the team envisions for which the technique offers potential value. For example, Whitehead said, medical implants that “have to be highly customized and conform to some kind of pre-existing geometry or biology and also have to be fairly robust. A lot of that lends itself to metal additive manufacturing,” and the team’s next step will be to prove that the technique works with metal. After that, there are a number of other possibilities, such as embedding electronics in print and burying a microchip inside, which now can only be done afterward.

Noting the benefit in creating knee and hip implants, for example, Lipson said they often require soft material at the core and hard material on the outside to prevent the implant from being stronger than the bone, which could cause the implant to break the bone. “You have to match it, and this is a very tricky thing. Multi-material is the way to do it, and now it’s not possible,” he said.

You May Also Like: 3D-Printed Algae Boosts Regenerative Medicine

Looking ahead, the team is excited about the prospects of combining different approaches to additive manufacturing. “Today you have to choose, do you want to go powder or liquid or do you want to go extruded plastic [FDM or Fused Deposition Modeling],” Lipson said. “You have to choose one, and then you’re stuck with it. Each has pros and cons. With our approach, you can do a little bit of this and a little bit of that, go back and forth and get the benefit of all. You can make something very strong with SLS but also smooth and watertight [with SLA (stereolithography), another form of 3D printing]. You can do all of them at the same time. It’s unexplored territory.

“My experience is that a lot of people are saying 3D printing was all hype. In 2015, it was all the rage. Now nobody’s talking about it. But (based on spending) on the technology and services and products around it, it’s still continuing to grow exponentially. Once this technology can expand from single material parts to multi-material parts, all bets are off. At that point, it’s going to explode in even more things.”

Nancy Giges is a technology writer based in White Plains, NY.

Register Today for the AM Industry Summit: Convergence of Aerospace & Energy